DIO-430-R1 Relay module 3-channel

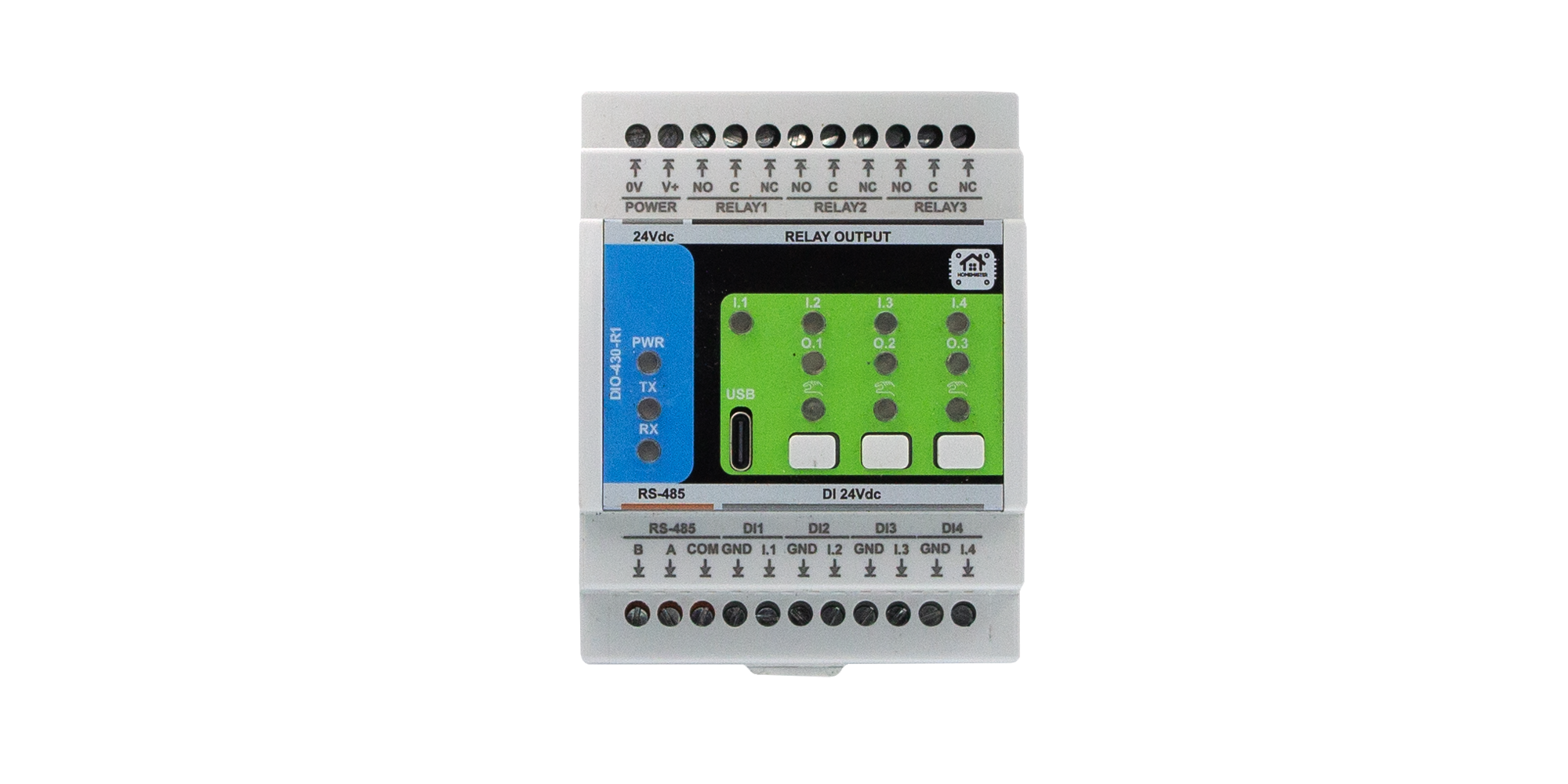

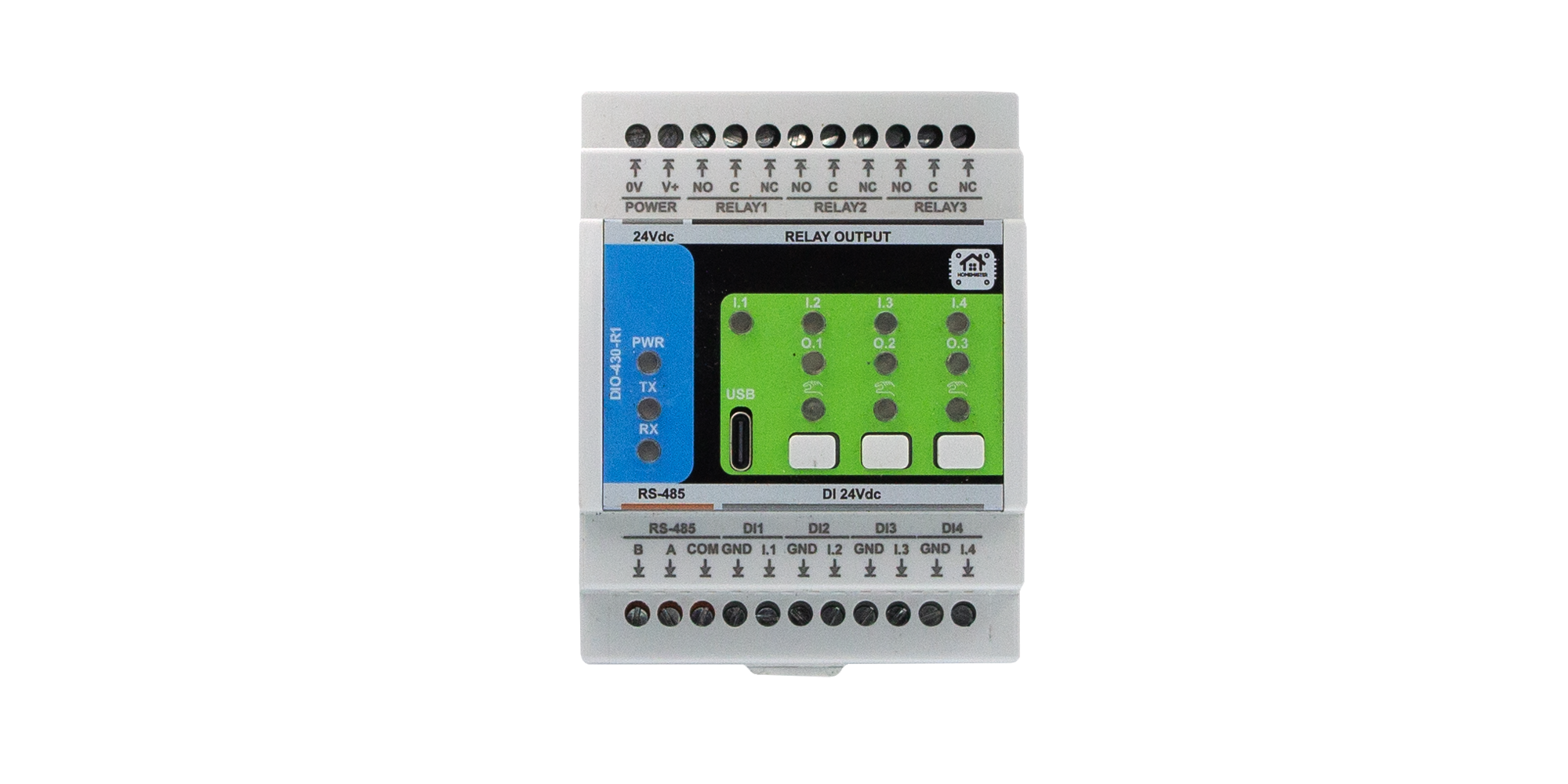

https://www.home-master.eu/shop/3-channel-relay-module-58 https://www.home-master.eu/web/image/product.template/58/image_1920?unique=1ec736dThe DIO-430-R1 is an industrial-grade digital I/O expansion module designed for relay switching and input monitoring over RS485 Modbus networks. Built for smart buildings and control systems, it provides opto-isolated inputs, high-current relays, and flexible local logic in a compact DIN-rail enclosure.

The module integrates seamlessly with the HomeMaster ecosystem and works as a Modbus slave device with MiniPLC, MicroPLC, Home Assistant, ESPHome, and industrial PLC systems.

The DIO-430-R1 brings professional digital input control and relay automation into modular automation systems. Each channel can be configured for toggle actions, pulse triggers, overrides, and alarm functions. This allows flexible behavior without relying entirely on the controller.

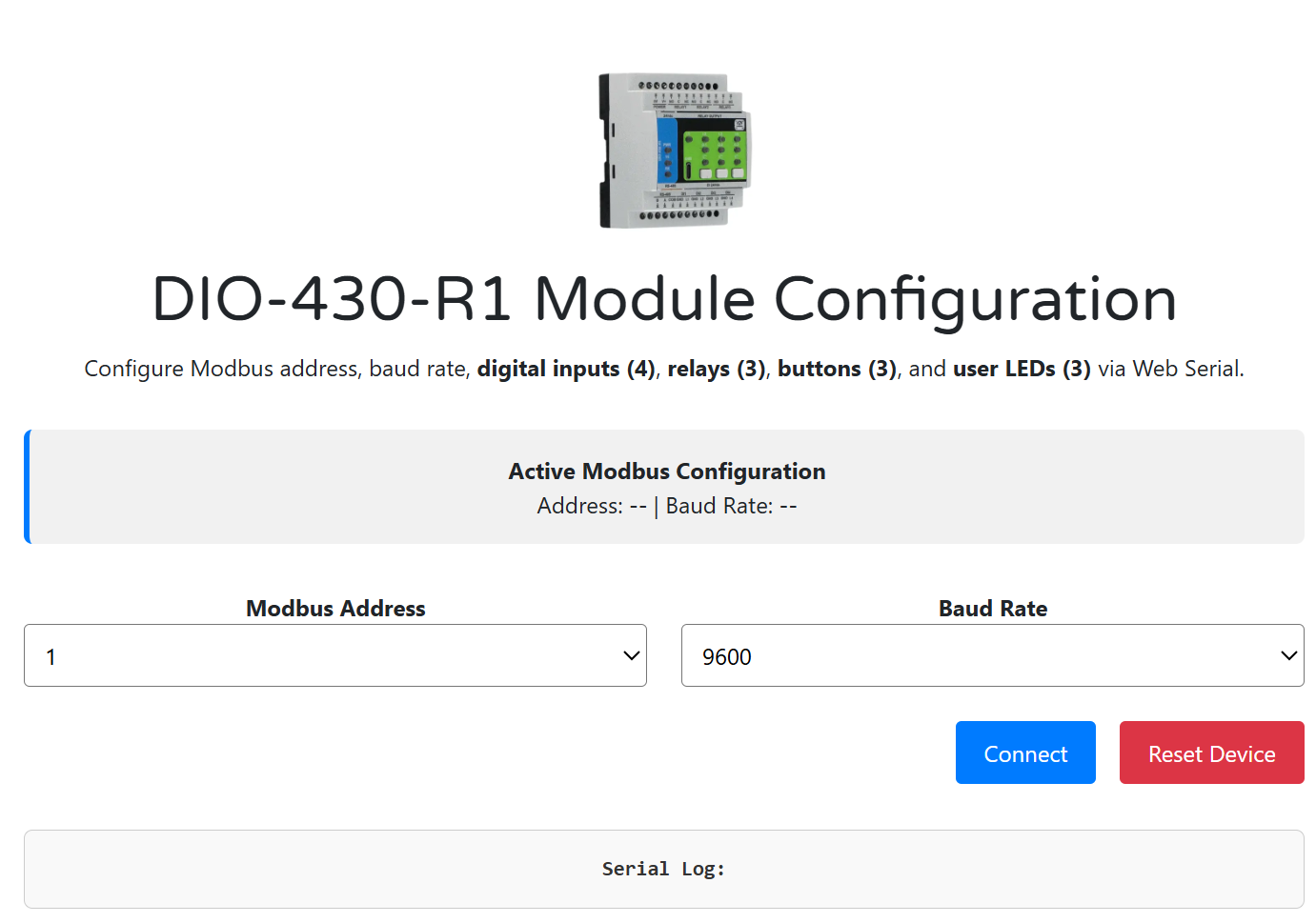

The built-in driverless WebConfig tool enables instant configuration through USB-C using a browser — no additional software required.

KEY BENEFITS

- 4 isolated digital inputs

- 3 high-current SPDT relays (16 A)

- RS485 Modbus RTU communication

- DIN-rail enclosure for control cabinets

- Configurable buttons and status LEDs

- USB-C WebConfig setup tool

- Local logic when controller is offline

- Persistent onboard configuration storage

- Surge, ESD and field protection

- Open-source firmware and hardware

Hardware & Control Features

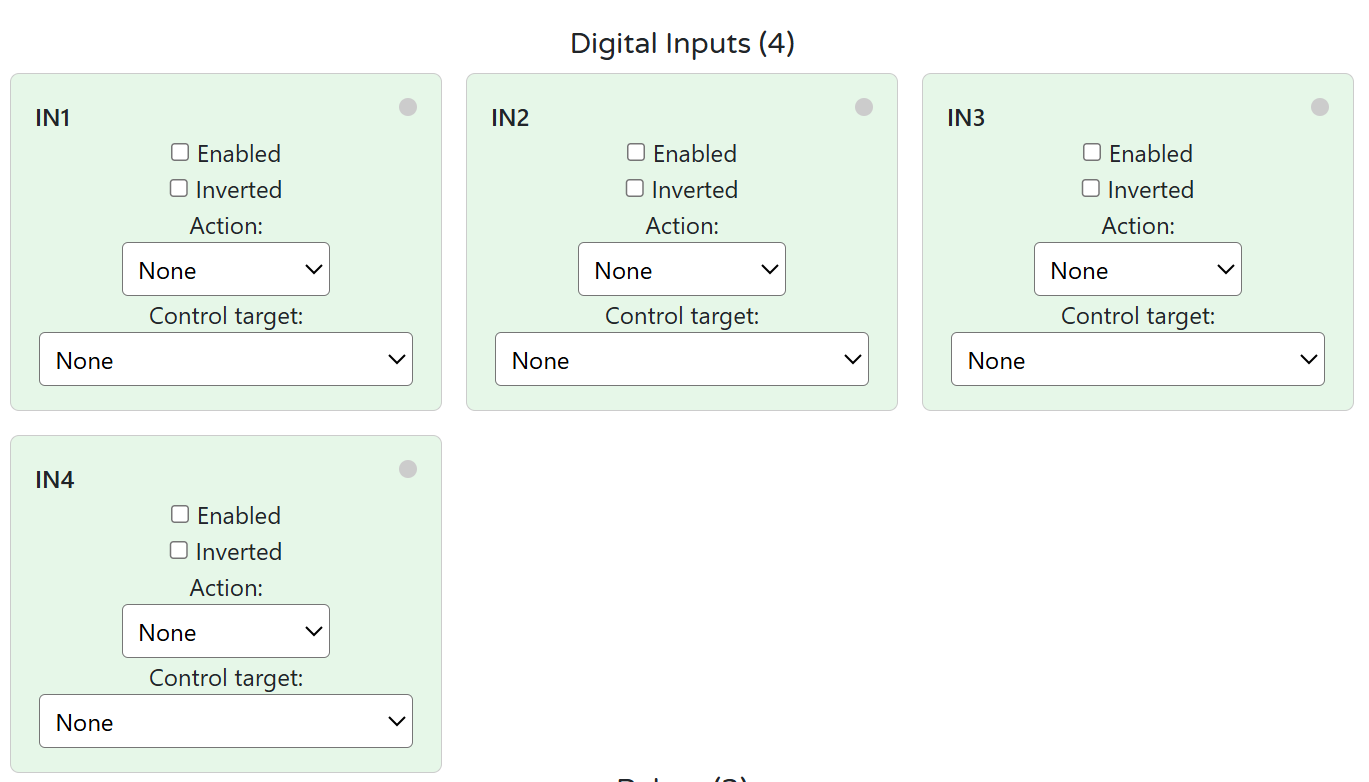

The DIO-430-R1 provides four galvanically isolated digital inputs designed for dry contacts or 24 V field signals. These inputs can directly control relays using built-in logic without requiring PLC processing.

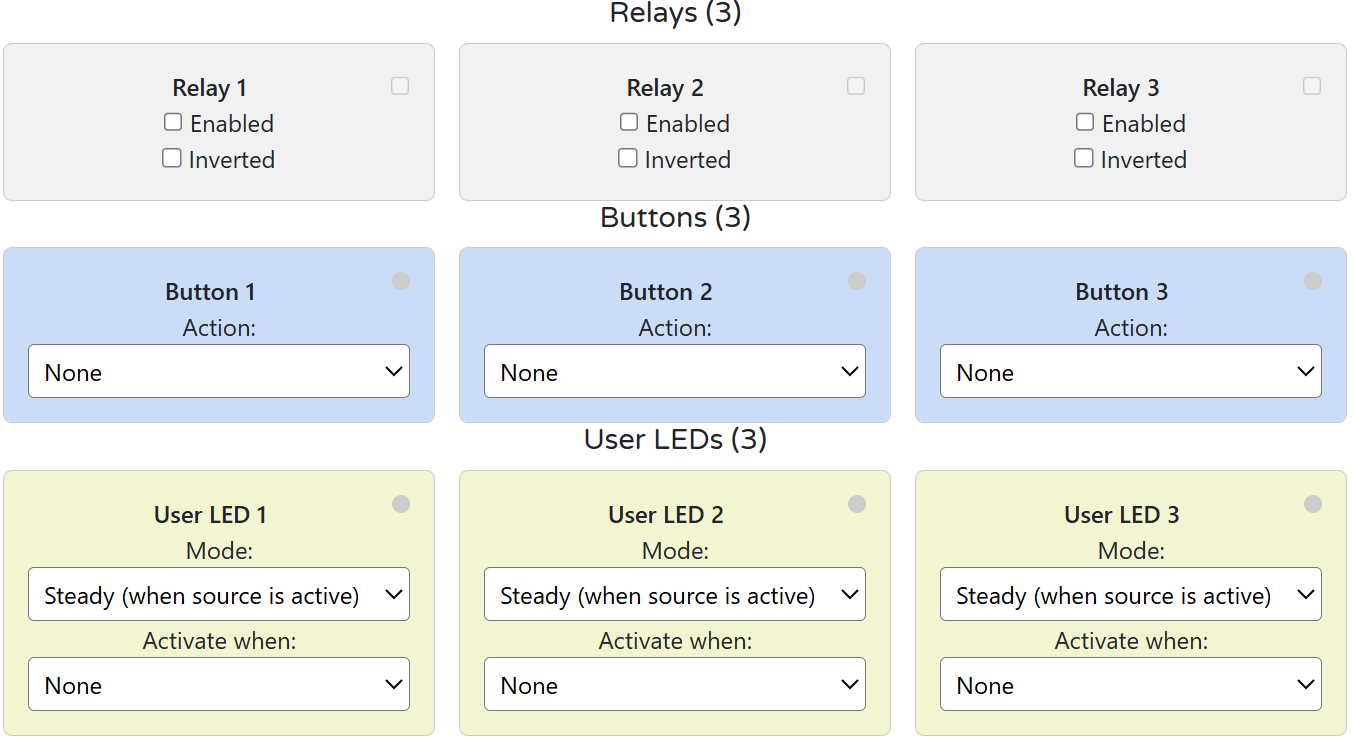

Three SPDT high-power relays allow direct switching of devices or interposing contactors. Each relay can be assigned a local button override or controlled via Modbus coils.

Web-based configuration supports:

- Input → relay mapping

- LED indicator modes (steady / blink)

- Button override logic

- Modbus address & baud rate setup

- Live diagnostics

All settings are stored permanently and restored on restart.

Built for Reliability

The DIO-430-R1 is engineered for electrically noisy environments:

- TVS surge protection

- Resettable fuses

- Galvanic input isolation

- Differential RS-485 line protection

- Overvoltage and polarity protection

The module continues local control even if the controller is offline, providing fail-safe behavior for critical automation systems.

Power & Installation

The DIO-430-R1 operates from 24 V DC (SELV) and mounts on a standard 35 mm DIN rail inside electrical cabinets.

Home Assistant & ESPHome Integration

The DIO-430-R1 integrates with Home Assistant through ESPHome using Modbus RTU packages. All relays and inputs appear as entities and can be used in dashboards and automation rules.

Designed for Professionals & Makers

Whether you are deploying industrial systems or DIY automation projects, the DIO-430-R1 provides robust digital control without proprietary restrictions. Firmware, schematics, and configuration tools are fully open-source, allowing complete system ownership.

Schematics:

Links:

GonfigTool

Back on Kickstarter

Be among the first to receive the HomeMaster products by backing our Kickstarter campaign.

- Early-bird rewards available while supplies last

- You’re only charged if the campaign reaches its goal

- Support reliable, local, open-source automation

Back on Kickstarter

Be among the first to receive the HomeMaster products by backing our Kickstarter campaign.

- Early-bird rewards available while supplies last

- You’re only charged if the campaign reaches its goal

- Support reliable, local, open-source automation

Display Name:

DIO-430-R1 Relay module 3-channel

DIO-430-R1 — Module for Smart I/O Control

HOMEMASTER – Modular control. Custom logic.

1. Introduction

The DIO-430-R1 is a configurable smart digital I/O module designed for digital input monitoring and relay-based output control in building automation, lighting, HVAC, alarms, and general control systems.

It offers 4 opto-isolated digital inputs, 3 high-current SPDT relays, 3 user buttons, and 3 configurable user LEDs. All I/O channels are individually configurable, allowing flexible logic such as toggle, pulse, manual override, and alarm indication.

It connects via RS-485 (Modbus RTU) to a MicroPLC, MiniPLC, or any compatible controller, and can also integrate with Home Assistant (ESPHome) or SCADA/PLC systems.

Configuration and diagnostics are performed through a driverless Web Serial interface via USB-C, using the browser-based WebConfig Tool. The module supports both master-controlled and standalone local logic modes.

| Subsystem | Qty | Description |

|---|---|---|

| Digital Inputs | 4 | Opto-isolated, dry contact compatible, noise-protected |

| Relays | 3 | SPDT (NO/NC), 16 A rated, dry contacts |

| LEDs | 3 | Configurable: Steady or Blink modes, linked to relays |

| Buttons | 3 | User-configurable for override or reset |

| Modbus RTU | Yes | RS-485 interface (Configurable: Addr 1–255, 9600–115200 baud) |

| USB-C | Yes | WebConfig tool access via Web Serial (Chrome/Edge) |

| Power | 24 V DC | Fused input, reverse-polarity and surge protected |

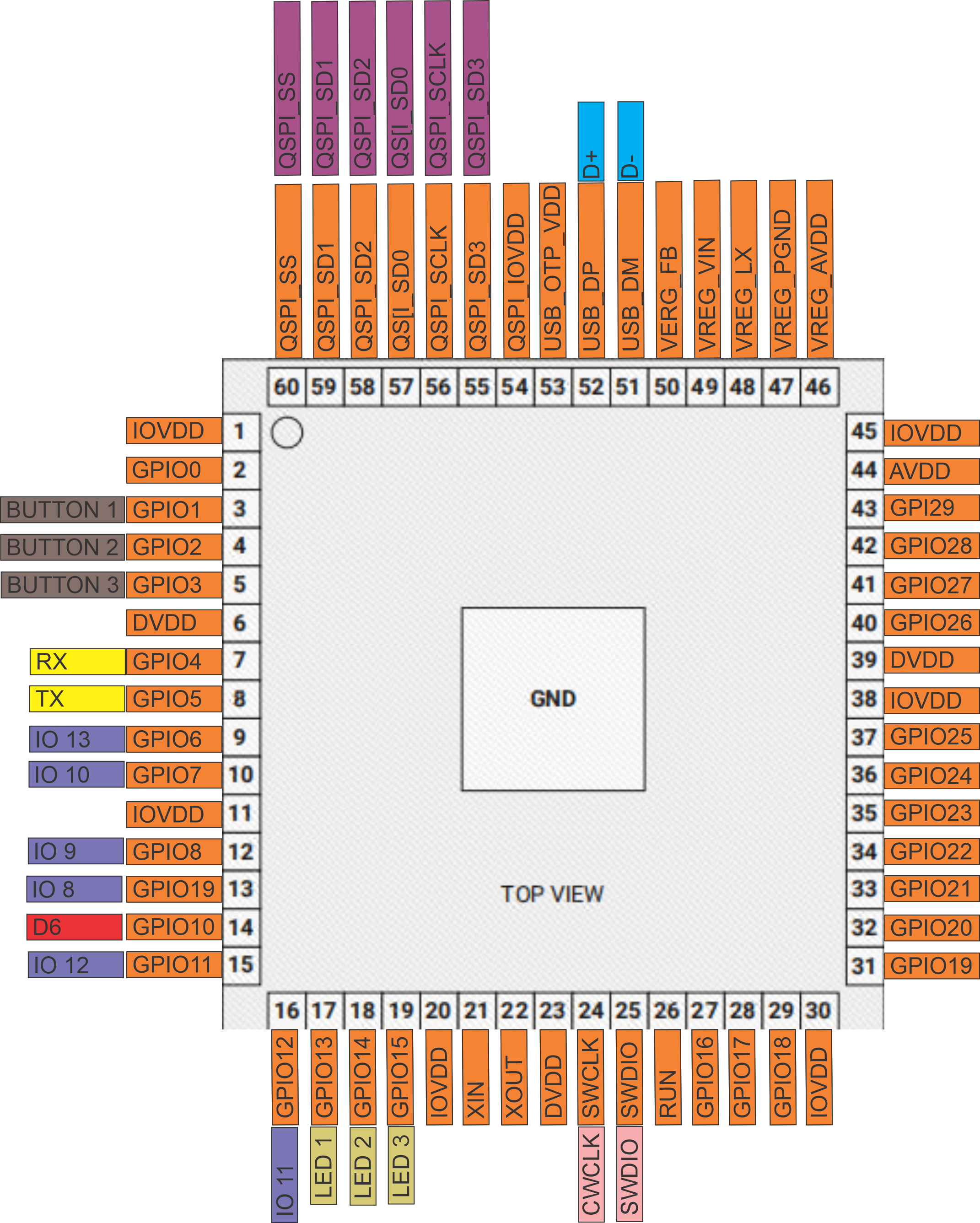

| MCU | RP2350 | Dual-core, with QSPI flash, USB, UART, LittleFS |

| Protection | TVS, PTC | ESD, surge, and short-circuit protection on I/O and power |

System Role & Communication

The module communicates over the RS-485 Modbus RTU bus, using A/B differential lines and a shared COM/GND reference. It supports poll-based communication, where a master device reads input states and writes relay commands.

All configuration — including input-to-relay mapping, LED modes, and button logic — is stored persistently in internal flash via LittleFS and can be changed live through USB-C + WebConfig.

Factory default communication settings:

- Modbus Address:

3 - Baud Rate:

19200 - Parity:

None - Stop Bits:

1

The module’s logic (input→relay mapping, LED modes, button behavior) is stored persistently in internal flash via LittleFS, and settings can be changed live using USB-C + WebConfig.

2. DIO-430-R1 — Technical Specification

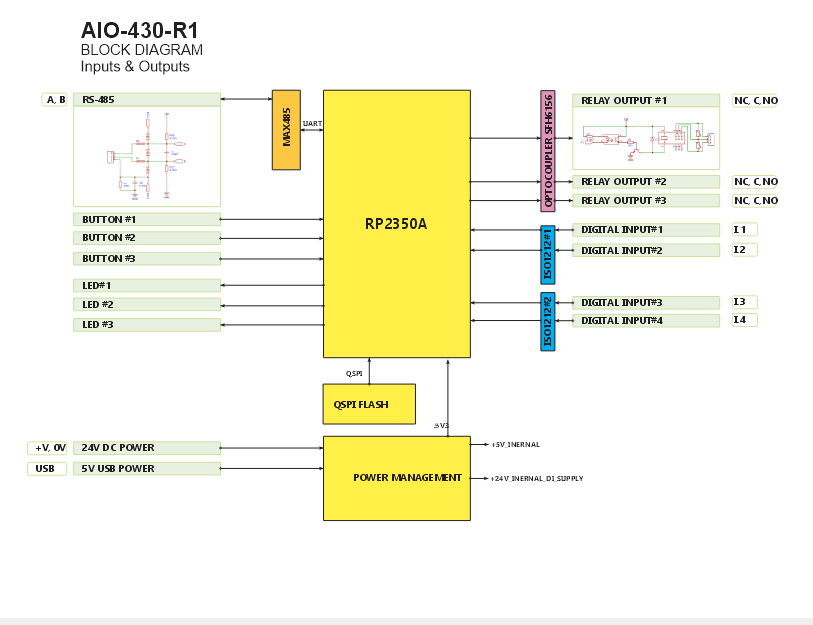

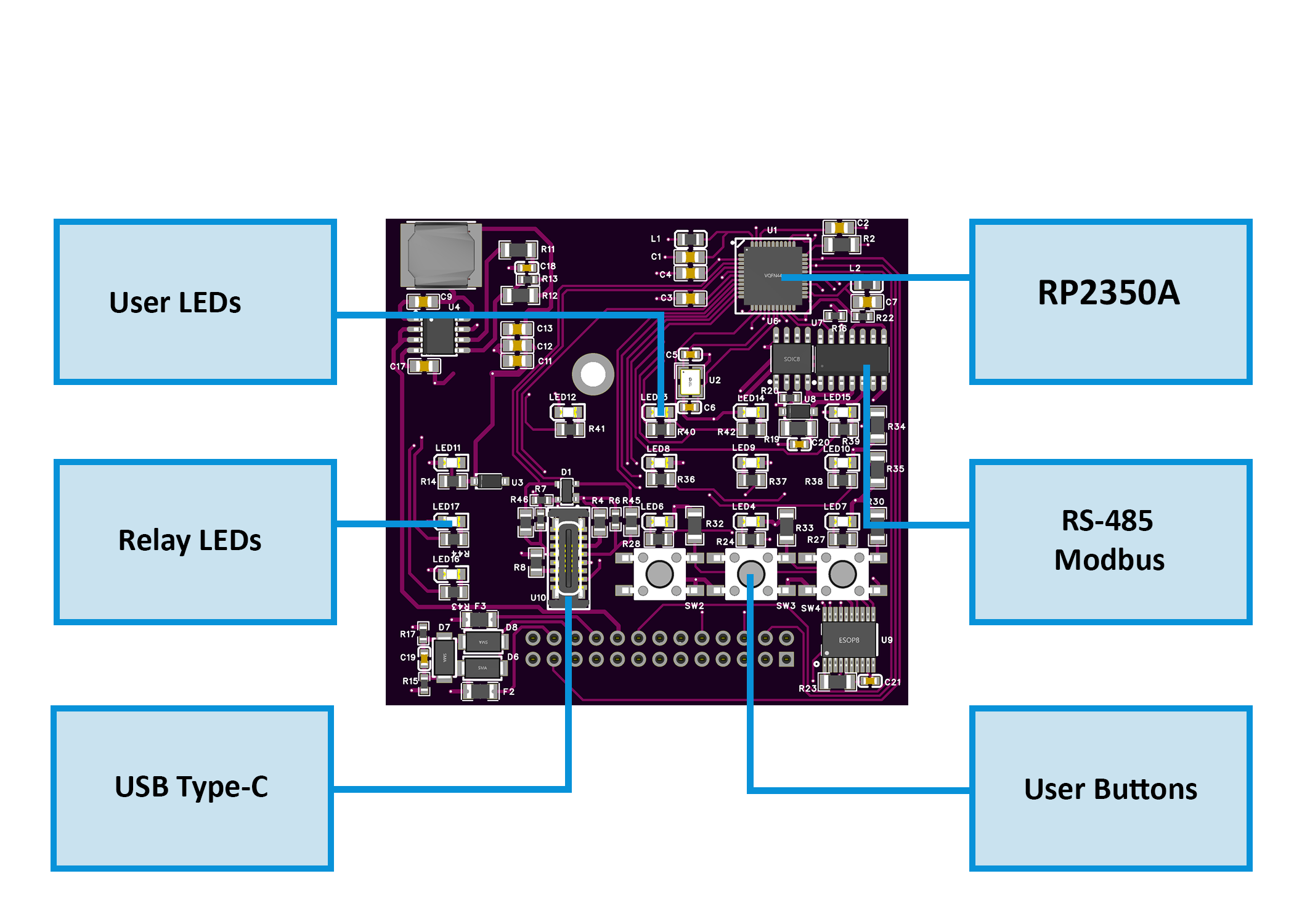

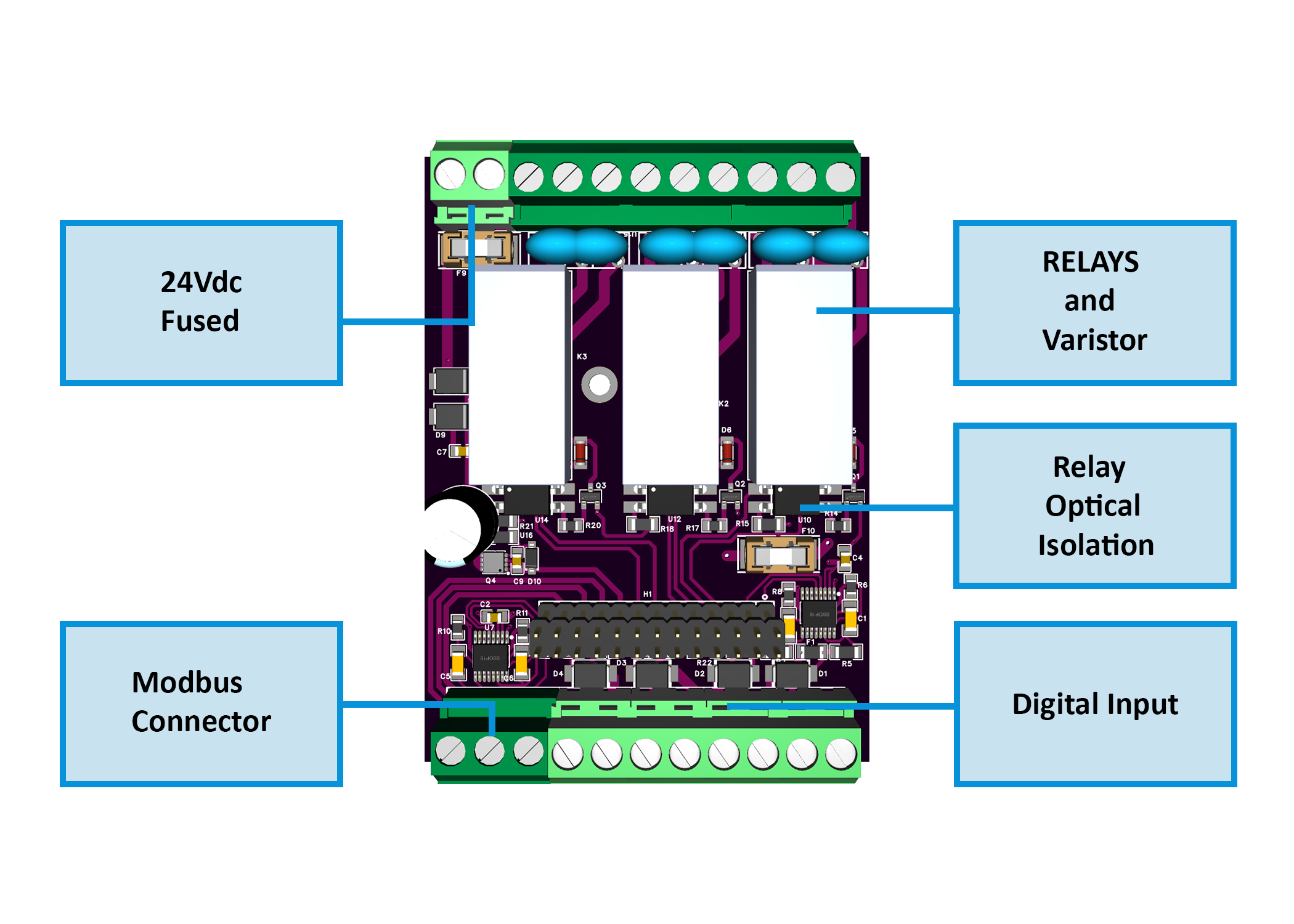

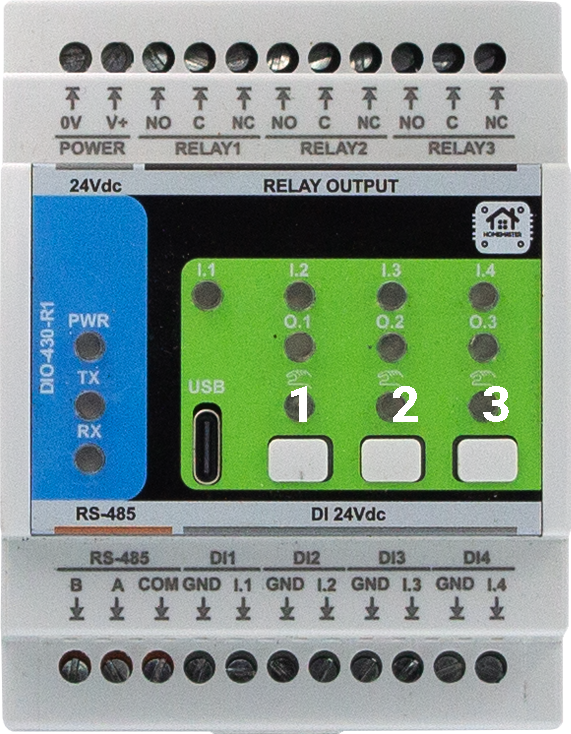

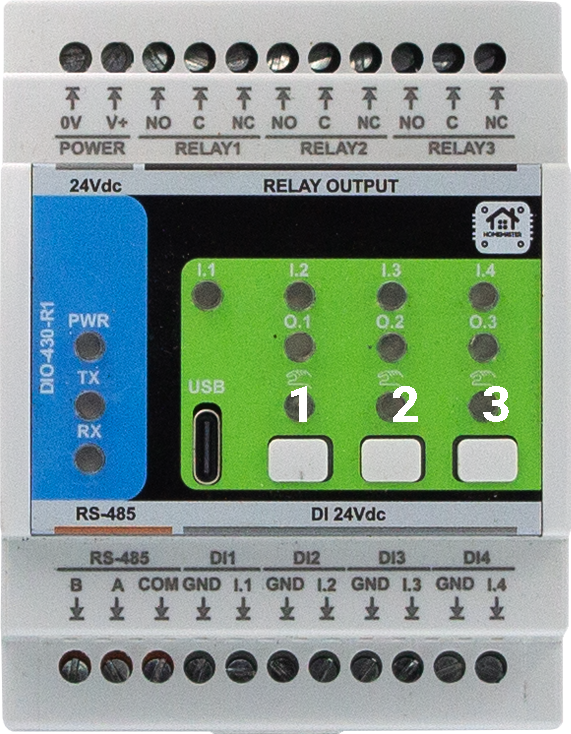

2.1 Diagrams & Pinouts

System overview, board callouts, and pin mapping:

2.2 I/O and Electrical Summary

| Interface | Qty | Description |

|---|---|---|

| Digital Inputs | 4 | Galvanically isolated (ISO1212 class). Supports dry contacts or 24 V signals. PTC + TVS per channel. |

| Relay Outputs | 3 | SPDT (NO/NC/COM), 16 A dry contacts. Use RC/MOV snubbers or interposing contactors for inductive/mains loads. |

| User LEDs | 3 | Configurable (Steady/Blink). Follow relay or logic status. |

| Buttons | 3 | Momentary. Configurable for relay override/toggle. |

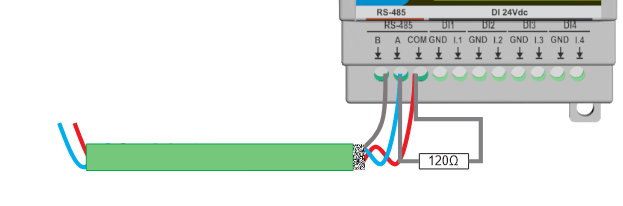

| RS-485 (Modbus RTU) | 1 | A/B/COM terminals. Daisy-chain topology. 120 Ω termination at both ends. |

| USB-C | 1 | Web Serial setup, diagnostics, and firmware flashing (ESD-protected). |

| Power Input | 1 | 24 V DC SELV. Reverse-polarity + surge protected. |

Electrical Ratings

| Parameter | Min | Typ | Max | Unit | Notes |

|---|---|---|---|---|---|

| Supply Voltage | 22 | 24 | 28 | V DC | SELV/PELV input |

| Logic Consumption | – | 1.5 | 3.0 | W | Excludes relay loads |

| Digital Input Range | 0 | 24 | 30 | V DC | Isolated, noise-protected |

| Relay Contact Current | – | – | 16 | A | SPDT dry contacts |

| Relay Contact Voltage | – | – | 250 | V AC | or 30 V DC max |

| RS-485 Data Rate | – | 19.2 | 115.2 | kbps | Default 19200 8N1 |

| USB-C Voltage | 4.75 | 5.0 | 5.25 | V DC | Service only |

| Operating Temp. | 0 | – | 40 | °C | ≤ 95 % RH, non-condensing |

Power budgeting: logic + LEDs + up to 3 relay coils + sensor loads → add ≥ 30 % PSU headroom.

2.3 Connectors & Terminal Map

| Block | Pins | Function | Notes |

|---|---|---|---|

| POWER | 0V, V+ | 24 V DC input | Reverse/surge protected |

| RELAY 1-3 | NO, C, NC | SPDT contacts | Add RC/MOV for inductive loads |

| DI 1-4 | INx, GNDx | Isolated digital inputs | 24 V field or dry contact |

| RS-485 | B, A, COM | Modbus RTU bus | Terminate 120 Ω at ends |

| USB-C | D+, D−, VBUS, GND | Setup / Service port | Not for field powering |

2.4 Reliability & Protection

- Reverse-path diode + high-side MOSFET on 24 V input.

- Local PTC + TVS protection on field interfaces.

- Relay drivers opto-isolated; RC/MOV suppression recommended.

- RS-485 with TVS, series protection, and fail-safe biasing.

- USB-C ESD-protected; CC resistors per spec.

- Non-volatile flash with auto-save after configuration changes.

2.5 Functional Overview

- Modbus RTU slave (factory Addr 3, 19200 8N1; configurable 1–255, 9600–115200).

- Inputs → Relays: per-input Enable/Invert/Action (

None/Toggle/Pulse) and Target (R1–R3orAll). - Buttons: assignable to relay override (toggle).

- LEDs: configurable Steady/Blink following relay status.

- Setup via WebConfig: USB-C → Chrome/Edge; set comms and I/O mapping.

- Persistent config: stored in LittleFS and restored on boot.

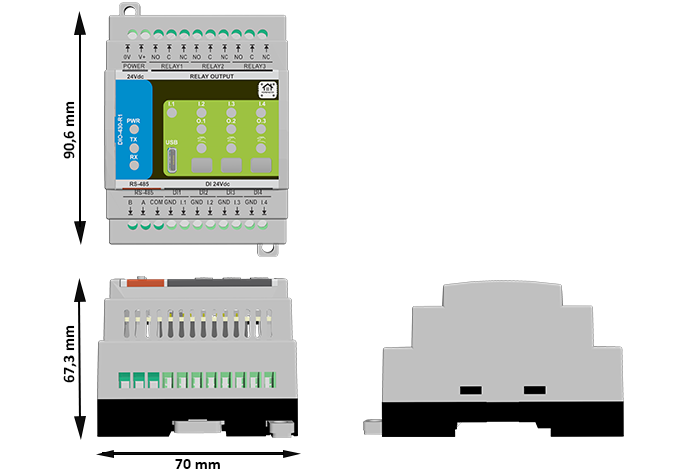

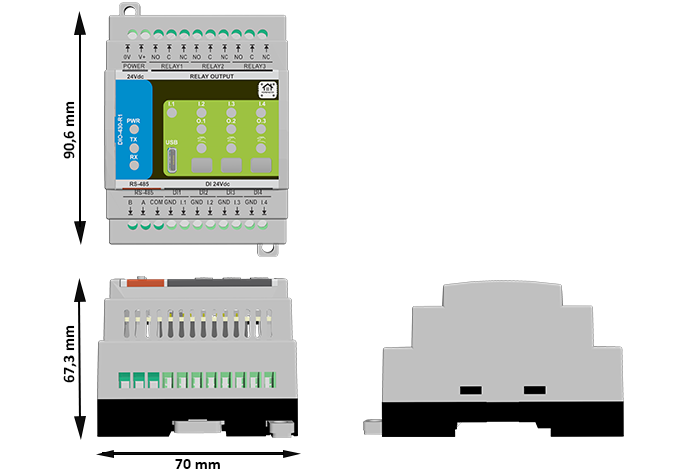

2.6 Mechanical & Environmental

| Property | Specification |

|---|---|

| Mounting | DIN-rail EN 50022 (35 mm) |

| Enclosure | PC/ABS V-0, panel mount |

| Dimensions | 70 × 90.6 × 67.3 mm (W × H × D) |

| Terminals | Pluggable 5.08 mm, 26–12 AWG (≤ 2.5 mm²), 0.5–0.6 Nm |

| Ingress Protection | IP20 (panel interior) |

| Operating Temp | 0–40 °C, ≤ 95 % RH (non-condensing) |

2.7 Standards & Compliance

| Standard / Directive | Description |

|---|---|

| Ingress Rating | IP20 (panel-mount only) |

| Altitude | ≤ 2000 m |

| Environmental | RoHS / REACH compliant components |

3. Use Cases

The DIO‑430‑R1 supports both lighting and motor/pump control — making it ideal for mixed automation tasks in smart homes, greenhouses, HVAC, and industrial setups.

Below are 3 versatile examples combining both types of loads.

3.1 Staircase Light with Motion Sensor + Circulation Pump

Automatically turns ON a staircase light and a circulation pump when motion is detected.

Setup Instructions:

- Set IN1 to

Action = Pulse,Target = Relay 1(light). - Set IN2 to

Action = Pulse,Target = Relay 2(pump). - Enable Relay 1 for the staircase lighting.

- Enable Relay 2 for the circulation pump.

- Set LED 1 =

Blink, source =Relay 1. - Set LED 2 =

Steady, source =Relay 2.

3.2 Manual Light + Fan Override (Wall Panel)

Wall-mounted buttons allow users to toggle lights and exhaust fans independently.

Setup Instructions:

- Assign Button 1 →

Relay 1 override (toggle)→ Room Light - Assign Button 2 →

Relay 2 override (toggle)→ Ventilation Fan - Enable both Relay 1 and Relay 2.

- Set LED 1 and LED 2 to

Steady, following respective relays. - Optionally use Modbus Coils

200–201for remote control.

3.3 Greenhouse Light + Irrigation Pump Automation

Lights and irrigation are controlled via digital inputs or remotely from a PLC.

Setup Instructions:

- IN3 →

Toggle, Target =Relay 1→ Grow Light - IN4 →

Pulse, Target =Relay 2→ Irrigation Pump - Enable Relay 1 and Relay 2.

- Assign Button 3 to

Relay 2 override (toggle)for manual watering. - Set LED 1 =

Steady(light status), LED 2 =Blink(pump running).

4. Safety Information

These guidelines apply to the DIO-430-R1 I/O module. Ignoring them may result in equipment damage, system failure, or personal injury.

⚠️ SELV/PELV Domains Only

- The DIO-430-R1 operates entirely within SELV/PELV low-voltage domains (e.g., 24 V DC, RS-485, USB 5 V).

- Do not connect mains voltage to any terminal. Use interposing contactors/PSUs for mains loads.

- Respect isolation boundaries: never bridge logic GND with isolated field grounds (e.g., GND_ISO / FGND).

- Connect sensor returns only to the isolated field ground; connect RS-485 COM/GND only within the same SELV domain.

4.1 General Requirements

| Requirement | Detail |

|---|---|

| Qualified Personnel | Installation and servicing must be done by qualified personnel familiar with 24 V control systems and RS-485. |

| Power Isolation | Disconnect the 24 V DC input before wiring. Lockout/tagout where applicable. |

| Environmental Limits | Mount in a clean, sealed enclosure; avoid condensation, conductive dust, or vibration. |

| Grounding | Bond the panel to PE. Keep RS-485 COM/GND shared with the controller side. |

| Voltage Compliance | SELV only on all terminals. Follow relay contact ratings on the product label/datasheet. Use upstream fusing and surge protection. |

4.2 Installation Practices

| Task | Guidance |

|---|---|

| ESD Protection | Handle by the enclosure/edge only. Use an antistatic wrist strap when the board is exposed. |

| DIN Rail Mounting | Mount securely on 35 mm DIN rail inside an IP-rated cabinet. Leave cable slack for strain relief. |

| Wiring | Use correct wire gauge and torque terminal screws. Separate power, DI, relay, and RS-485 harnesses. |

| Isolation Domains | Respect isolation: do not bridge logic GND to isolated field grounds (e.g., GND_ISO/FGND). Keep analog/sensor returns on the isolated side. |

| Commissioning | Before power-up, verify polarity, relay NO/NC routing, RS-485 A/B orientation and termination. |

4.3 I/O & Interface Warnings

🔌 Power

| Area | Warning |

|---|---|

| 24 V DC Input | Use a clean, fused SELV supply. Reverse-polarity protection exists but may disable the module when triggered. |

| Sensor Rail | Power sensors from a SELV rail. Observe polarity. Fuse external branches as required. |

| Surge/Noise | In noisy panels, add upstream surge/EMI suppression and keep high-current wiring away from control wiring. |

⏽ Inputs (Digital)

| Area | Warning |

|---|---|

| Type | Dry contact / 24 V signaling only, per your standard. Do not inject mains or undefined levels. |

| Isolation | Inputs are isolated from logic. Keep sensor returns on the field/isolated domain; do not bond to logic GND. |

| Debounce | Firmware provides debounce, but route away from contactors/VFDs and use shielded/twisted pairs for long runs. |

| Polarity | Configure invert/action in WebConfig; verify state transitions after wiring. |

⚙️ Relays (Outputs)

| Area | Warning |

|---|---|

| Contact Type | SPDT (NO/NC/COM) dry contacts. Follow the contact rating on the device label/datasheet. |

| Inductive Loads | For motors/solenoids/contactors, add an RC snubber or MOV at the load. Consider interposing relays/ contactors for higher power. |

| Separation | Keep relay load wiring physically separate from signal wiring. De-energize before servicing. |

| Verification | After wiring, verify NO/NC behavior and load polarity before enabling automation. |

🖧 RS-485 (Modbus RTU)

| Area | Warning |

|---|---|

| Topology | Use twisted pair; daisy-chain (no stubs). Terminate with 120 Ω at both physical ends. |

| Polarity | Maintain A/B polarity consistently. Share COM/GND reference between nodes (same SELV domain). |

| EMC | Route away from VFDs, contactors, and mains bundles. Use shielded cable in high-EMI environments. |

| Protection | Port includes protection, but good wiring practice is still required to avoid transients. |

🔌 USB-C (Front / Setup)

| Area | Warning |

|---|---|

| Purpose | Setup & maintenance only (WebConfig / firmware). Not intended for powering field devices. |

| ESD/EMI | Avoid hot-plugging in high-EMI areas. Use a grounded service laptop. Disconnect after commissioning. |

🔆 Front Panel (Buttons & LEDs)

| Area | Warning |

|---|---|

| Buttons & LEDs | Buttons can override relays; document operating procedures. Lock out overrides for safety-critical installs. |

🛡️ Shielding & EMC

| Area | Recommendation |

|---|---|

| Cable Shields | Terminate shields at one end (typically the PLC/controller). Keep runs short and away from high-voltage/EMI sources. |

✅ Pre-Power Checklist

- No bridge between logic GND and isolated GND_ISO/FGND

- A/B polarity and 120 Ω termination confirmed at bus ends

- not exceed the contact rating; snubbers added for inductive loads

- dry contact/SELV only; sensor polarity and returns verified

5. Installation & Quick Start

The DIO-430-R1 joins your system over RS-485 (Modbus RTU). Setup has two parts:

- Physical wiring, 2) Digital configuration (WebConfig → optional PLC/ESPHome).

5.1 What You Need

| Category | Item / Notes |

|---|---|

| Hardware | DIO-430-R1 — DIN-rail module with 4× DI, 3× SPDT relays, 3× buttons, 3× LEDs, USB-C, RS-485. |

| Controller (master) | HomeMaster MiniPLC/MicroPLC or any Modbus RTU master. |

| 24 VDC PSU (SELV) | Regulated 24 VDC; size for logic + relay coils + sensors; inline panel fuse/breaker. Power input stage includes fuse/TVS/reverse-polarity protection. |

| RS-485 cable | Twisted pair for A/B + COM/GND reference, 120 Ω termination at both ends of the trunk. |

| USB-C cable | For WebConfig via a Chromium browser (service/commissioning). |

| Software | Chromium-based browser with Web Serial (Chrome/Edge). Web page exposes Address/Baud + I/O mapping. |

| Field I/O | Dry contacts to DI1…DI4 (isolated front-end per channel). Relays (NO/NC/COM) drive LV loads or interposing contactors; add RC/MOV snubbers for inductive loads. |

Quick path: mount → wire 24 VDC + RS-485 A/B/COM → connect USB-C → WebConfig: set Address/Baud + map inputs → relays/LEDs → disconnect USB → hand over to controller.

5.2 Power

The module uses 24 VDC primary. Onboard regulation provides 5 V → 3.3 V for logic; DI front-end is isolated.

5.2.1 Supply Types

- 24 VDC DIN-rail PSU → 24Vdc(+) / 0V(–) power terminals (top row: POWER).

- Sensor side (DI) — isolated input receivers accept field signals; feed your sensors from the 24 V field rail and return to the DI GND pins (per-channel). Do not back-power logic from sensor rails.

5.2.2 Sizing (rule of thumb)

Account for:

- Base electronics + LEDs

- Relay coils (up to 3 simultaneously)

- Sensor rails (DI field side, if powered from the same 24 V source)

Size PSU for worst-case relays + sensors, then add ≥30 % headroom.

5.2.3 Power Safety

- Correct polarity; keep logic GND and DI field ground separate (respect isolation domains).

- Keep upstream fusing/breaker in place; the board also has input fuse/TVS/reverse-polarity MOSFET.

- Use snubbers on inductive loads; prefer interposing contactors for motors/pumps.

- De-energize before wiring; check shorts before power-up.

5.3 Networking & Communication

Runtime control is via RS-485 (Modbus RTU). USB-C is for local setup/diagnostics (Web Serial).

5.3.1 RS-485 (Modbus RTU)

Physical

- Terminals (lower front row): B, A, COM/GND → then DI and DI-GNDs. Maintain A/B polarity, share the COM/GND reference with the controller.

- Cable: Twisted pair (preferably shielded) for A/B + reference.

- Termination: 120 Ω at both physical ends of the trunk; avoid stubs.

Protocol

- Role: RTU slave; controller is master.

- Address: 1–255. Factory default: Address 3, 19200 8N1.

- Required: Dedicated 24 VDC power (bus is data-only).

Checklist

- A→A, B→B, COM→COM (GND ref).

- Two end terminations only; daisy-chain topology.

- Consistent A/B polarity end-to-end.

5.3.2 USB-C (WebConfig)

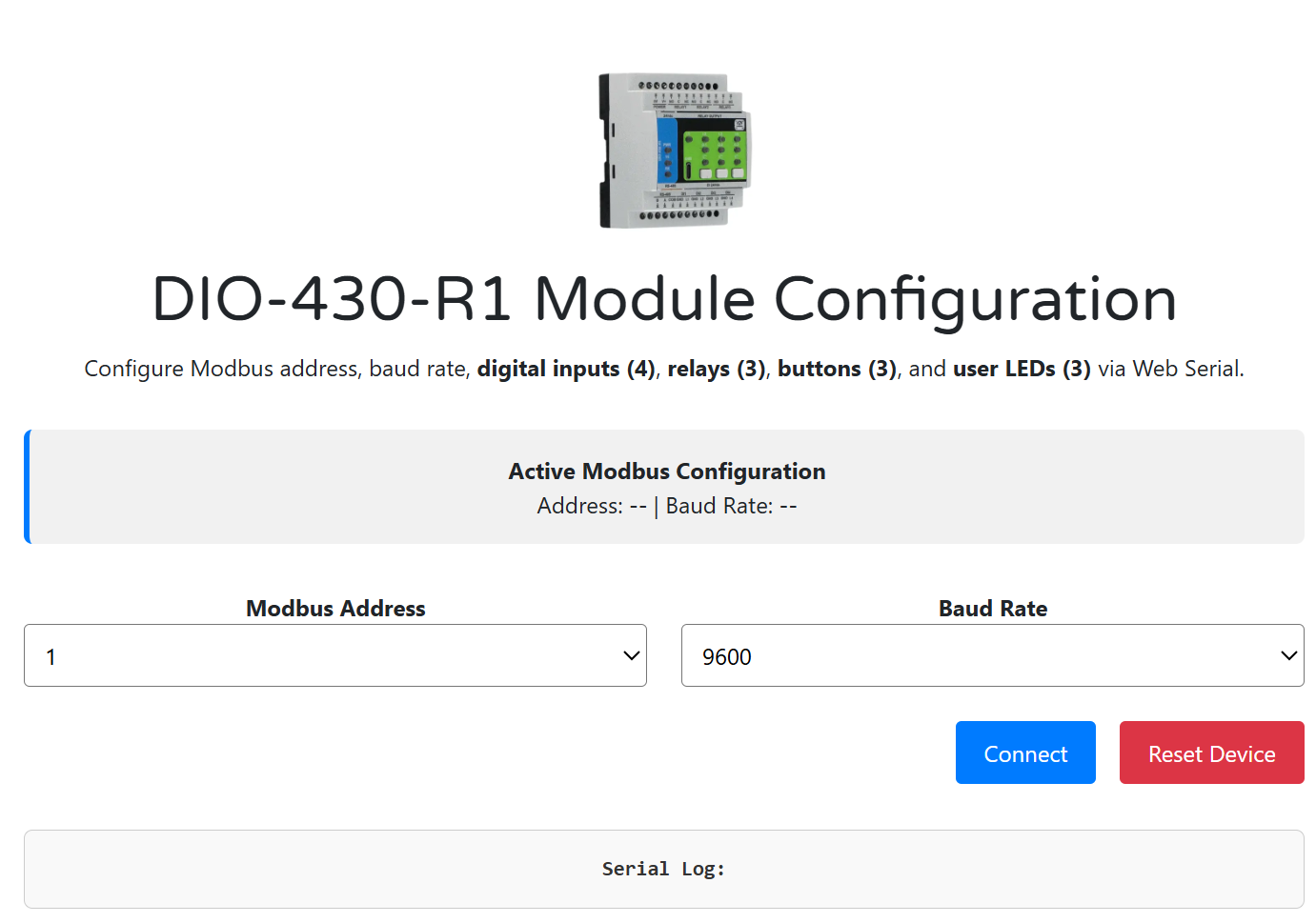

Purpose: Chromium (Chrome/Edge) Web Serial setup/diagnostics page.

Steps

- Connect USB-C to the module.

- Open the DIO-430-R1 WebConfig page and click Connect.

- Set Modbus Address & Baud (header shows Active Modbus Configuration).

- Configure Inputs / Relays / LEDs / Buttons; changes apply live and are saved to flash.

- Use Reset Device from the page if needed (dialog confirms).

If Connect is disabled: ensure Chromium + serial permission; close other apps that might hold the port.

5.4 Installation & Wiring

This section shows typical wiring for power, inputs, relays, RS-485, and the USB-C service port.

⚠️ Work on de-energized equipment only. Use SELV/PELV supplies for logic and field inputs. Mains on relay contacts must be wired by qualified personnel.

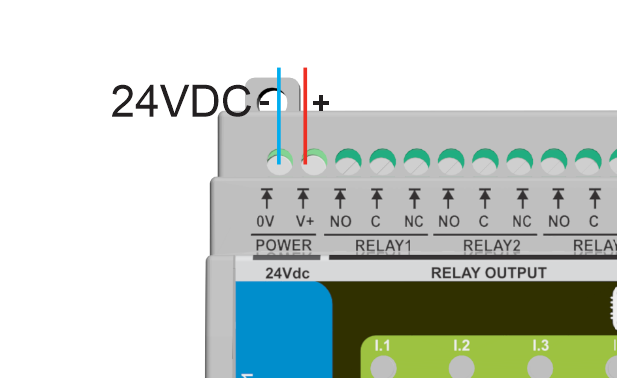

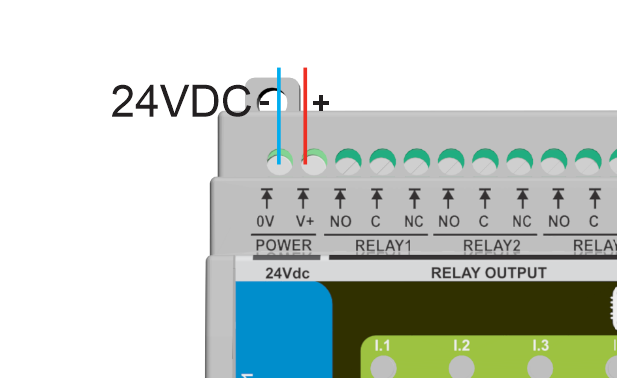

A) Power — 24 VDC (SELV)

Wire the regulated 24 VDC supply to the top POWER terminals: V+ and 0V.

Notes

- Keep V+/0V as a twisted pair; route away from motor cables/contactors.

- The module includes input protection (fuse/TVS/reverse-polarity MOSFET).

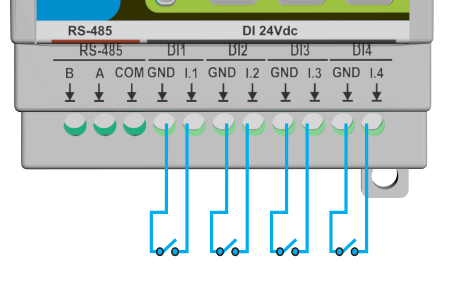

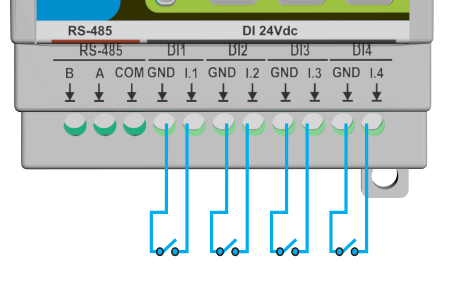

B) Digital Inputs (DI1…DI4)

Each input is isolated. Land the contact/sensor on INx with the paired GNDx return.

Tips

- Supports dry contacts or compatible 24 V field signals.

- Configure in WebConfig: Enabled/Invert, Action (

None / Toggle / Pulse), Control target (None / All / R1 / R2 / R3). - Keep field wiring shielded/twisted for long runs; terminate shield at one end only.

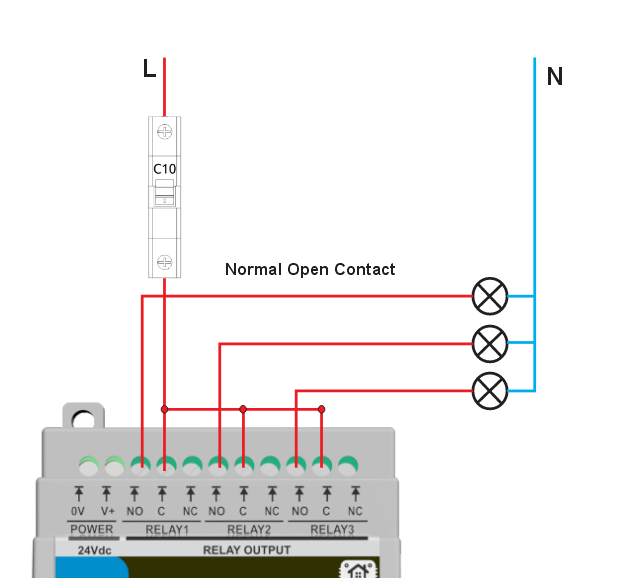

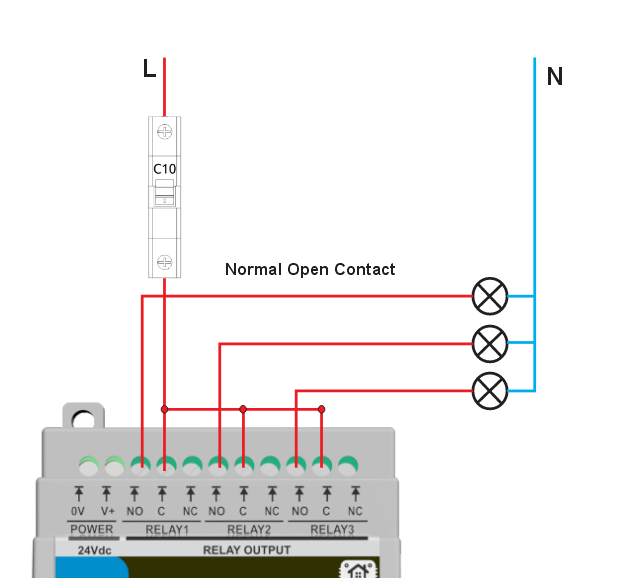

C) Relay Outputs (R1…R3)

Relays provide dry SPDT contacts (NO/NC/COM) for switching low-voltage loads or driving an interposing contactor for mains/inductive loads.

Best practices

- Add RC/MOV snubbers across inductive loads (fans, pumps, contactors).

- Keep load and logic wiring separated; observe conductor ratings and local code.

D) Sensor Rails (12 V / 5 V)

This module does not export auxiliary 12 V/5 V rails for field devices.

- Power sensors from your panel 24 V rail (or external rails as required).

- Return sensor commons to the matching DI GNDx terminals; do not bond field ground to logic GND.

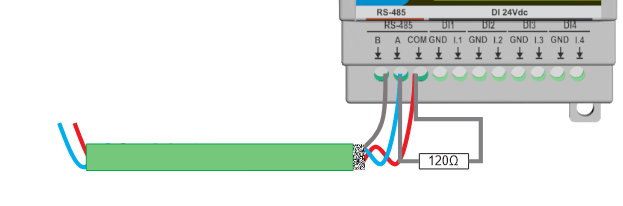

E) RS-485 (Modbus RTU)

The lower left terminals expose B, A, and COM (GND). Use shielded twisted pair and daisy-chain topology.

Checklist

- Wire A→A, B→B, and share COM/GND with the controller.

- Terminate the two physical bus ends with 120 Ω.

- Default protocol: Address 3, 19200 8N1 (change via WebConfig).

F) USB-C (Service / WebConfig)

- Use USB-C for commissioning and diagnostics only (Web Serial in Chrome/Edge).

- Not for powering field devices. Disconnect after setup and hand control to the RS-485 master.

5.5 Software & UI Configuration

Use the WebConfig page (USB-C + Chrome/Edge) to set Modbus comms and map I/O. Changes apply immediately and are saved to flash.

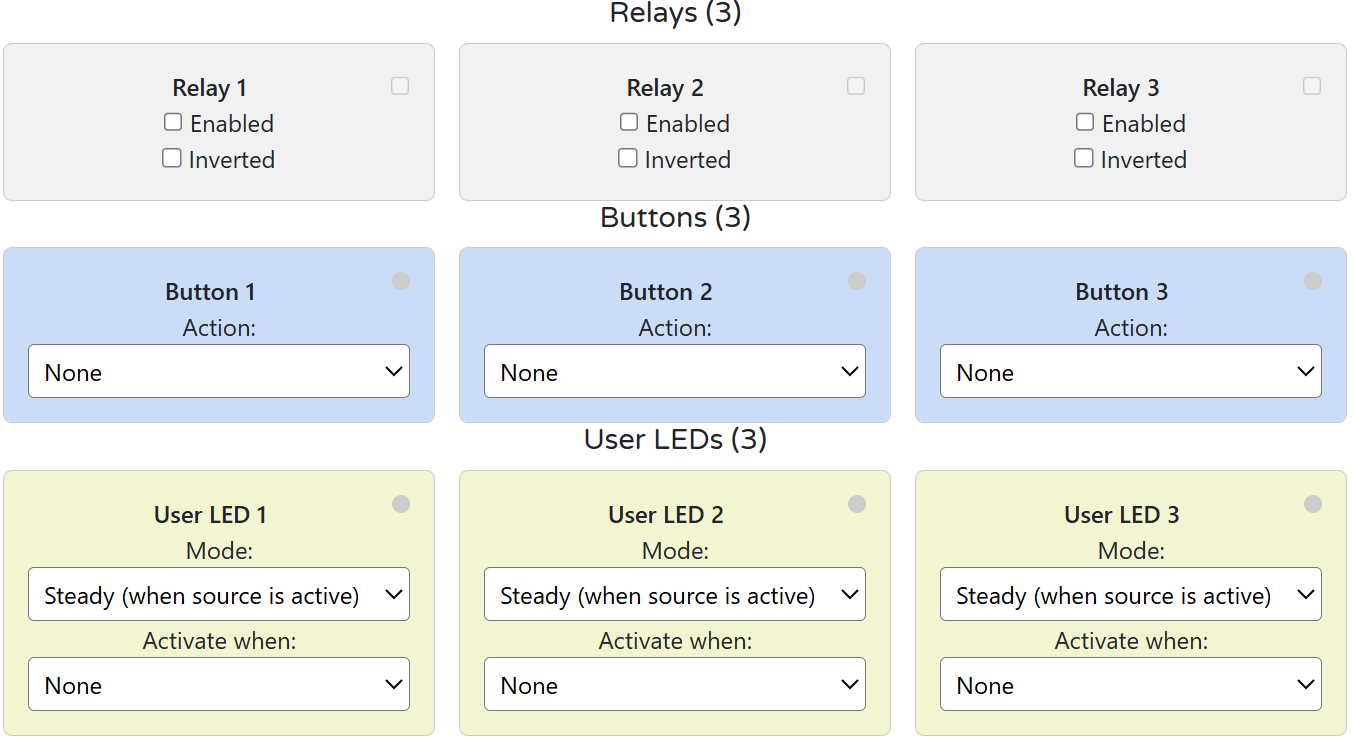

Screens shown below are from the DIO-430-R1 WebConfig.

A) WebConfig setup (Address & Baud)

- Connect the module via USB-C → open the WebConfig page → click Connect.

- In Modbus Address, choose 1–255 (factory default 3).

- In Baud Rate, select 9600–115200 (factory default 19200 8N1).

- Confirm the Active Modbus Configuration banner updates (Address/Baud).

Default values (Addr 3, 19200 8N1) are also noted in the module docs.

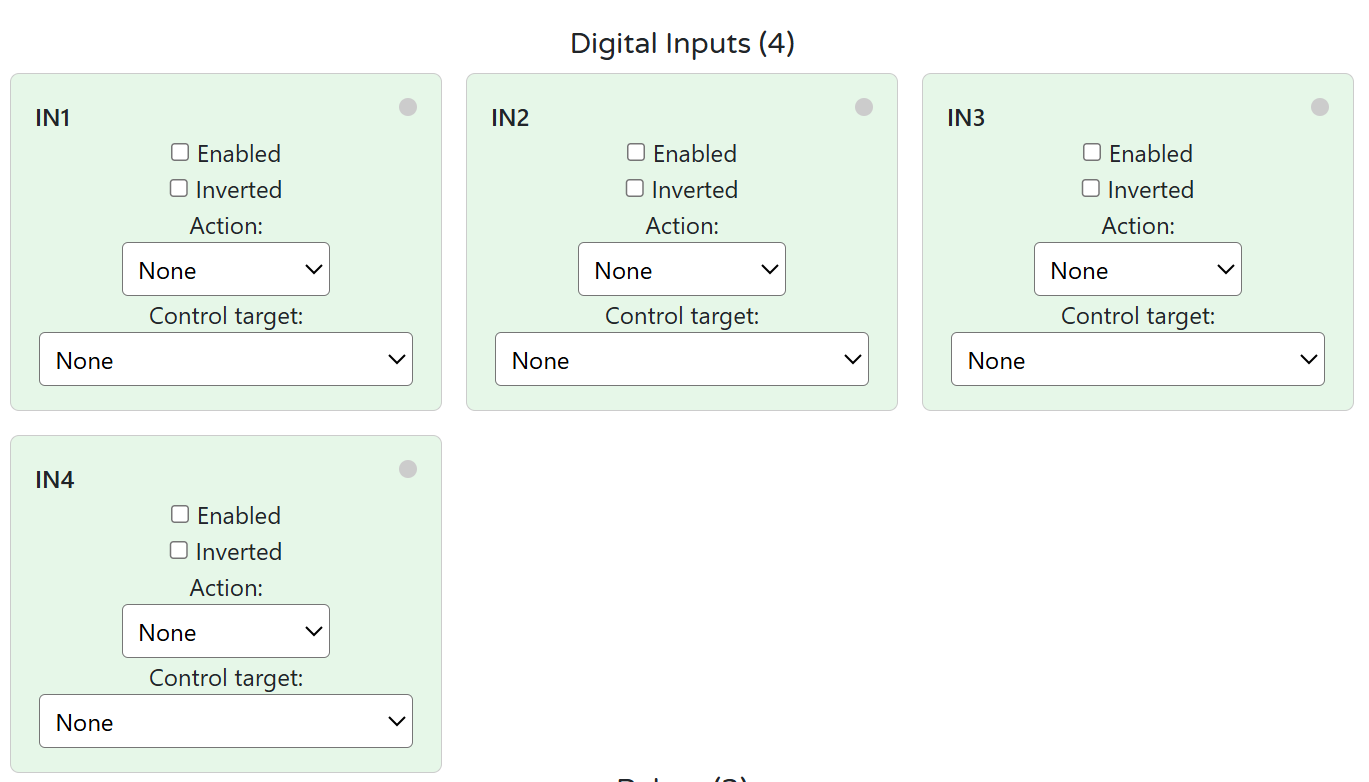

B) Inputs — enable / invert / group (control target)

Each IN1…IN4 card provides:

- Enabled: include the input in logic.

- Inverted: logical inversion.

- Action:

None / Toggle / Pulse. - Control target:

None / Control all / Relay 1 / Relay 2 / Relay 3.

This matches the firmware’s input options and allows direct mapping from inputs to one or more relays without a PLC.

Tips

- Use Toggle to latch a relay on each press; Pulse for momentary actions (timers handled by controller if needed).

- For “group” behavior, select Control all to operate Relays 1–3 together.

C) Relays — logic mode (group/manual)

For Relay 1–3:

- Enabled: relay is controllable.

- Inverted: invert drive polarity (use only if required by wiring).

Logic modes in practice

- Group control: Achieve via Input Control target = Control all (see Inputs section).

- Manual / local override: Assign Buttons (below) to toggle a specific relay even when the PLC also controls it.

D) LED and Button mapping

Buttons (3)

- Action: choose

Noneor Relay override (toggle) for Relay 1/2/3. This provides local/manual control without a PLC.

User LEDs (3)

- Mode:

SteadyorBlink(active when source is ON). - Activate when: select the source relay to follow (e.g., LED1 foll

5.6 Getting Started (3 Phases)

Phase 1 — Wire

- 24 VDC to V+ / 0V (GND) (top POWER terminals)

Use a regulated SELV supply; keep pairs twisted. - Digital inputs (IN1–IN4): dry contacts → INx / GNDx

Respect isolation domains; do not bridge logic GND ↔ field GND. - Relay outputs (R1–R3): COM / NO / NC

Prefer interposing contactors for motors/pumps; add RC/MOV snubber on inductive loads. - RS-485: A / B / COM (GND)

Shielded twisted pair; daisy-chain; terminate bus ends with 120 Ω. - USB-C (service): for WebConfig only (no field powering).

👉 See: Installation & Quick Start

Phase 2 — Configure (WebConfig)

- Open

https://www.home-master.eu/configtool-dio-430-r1in Chrome/Edge. - Connect USB-C → Select port → Connect.

- Set:

- Modbus Address / Baud (default: Addr 3, 19200 8N1)

- Inputs: Enable / Invert / Action (

None / Toggle / Pulse) / Control target (None / All / R1 / R2 / R3) - Relays: Enable (optional Invert)

- Buttons: map to Relay override (toggle) (R1/R2/R3)

- User LEDs: Mode (

Steady / Blink) + Activate when (follow a relay)

- Click Reset Device if prompted; settings auto-save to flash.

👉 See: WebConfig UI

Phase 3 — Integrate (Controller)

- Connect controller (MiniPLC/MicroPLC/PLC/SCADA/ESPHome) via RS-485.

- Match address and baud.

- Poll:

- Discrete inputs for DI states and relay states (per your mapping)

- Write:

- Coils to control relays (e.g., R1/R2/R3 ON/OFF)

- Use with:

- HomeMaster MicroPLC / MiniPLC

- ESPHome / SCADA / PLC

👉 See: Modbus RTU Communication & Integration Guide

✅ Verify

| Area | What to Check |

|---|---|

| LEDs | PWR = ON; TX/RX blink during RS-485 traffic |

| Inputs | Toggling a wall switch/sensor changes INx state in WebConfig/Modbus |

| Relays | Coil writes toggle R1–R3; loads switch correctly; snubber installed for inductive loads |

| Address/Baud | Controller reads module at the configured address/baud without errors |

| Isolation | No unintended bond between logic GND and DI field GNDx |

6. Modbus RTU Communication

Role: RTU slave (controller is master)

Defaults: Address 3, 19200 8N1 (change in WebConfig → Modbus)

Addressing shown below uses zero-based offsets (e.g., Holding Reg

40000= offset0).

If your master uses 1-based display (e.g., 40001), add +1 to the register number.

6.1 Address Range & Map (Overview)

| Type | Range (offsets) | Purpose |

|---|---|---|

| Coils (0x) | 00000…00031 |

Relay commands, device control |

| Discrete Inputs (1x) | 10000…10031 |

DI states, relay echo states |

| Input Registers (3x) | 30000…30031 |

Read-only status (masks, counters) |

| Holding Registers (4x) | 40000…40063 |

Config & runtime parameters (DI actions/targets, relay/LED/button settings, comms) |

6.2 Coils (0x) — Commands

| Coil | Name | Description |

|---|---|---|

00000 |

R1_CMD | Relay 1 ON/OFF (write 1/0) |

00001 |

R2_CMD | Relay 2 ON/OFF |

00002 |

R3_CMD | Relay 3 ON/OFF |

00010 |

SAVE_CFG | Persist current settings to flash (write 1) |

00011 |

RESET | Soft reset device (write 1) |

Coils drive relays regardless of input mappings (local buttons still work as overrides).

6.3 Discrete Inputs (1x) — States

| DI | Name | Description |

|---|---|---|

10000 |

DI1_STATE | Digital Input 1 (after invert option) |

10001 |

DI2_STATE | Digital Input 2 |

10002 |

DI3_STATE | Digital Input 3 |

10003 |

DI4_STATE | Digital Input 4 |

10010 |

R1_STATE | Relay 1 actual state (echo) |

10011 |

R2_STATE | Relay 2 actual state |

10012 |

R3_STATE | Relay 3 actual state |

6.4 Holding Registers (4x) — Configuration & Runtime

6.4.1 Identity / Comms

| Reg | Name | R/W | Encoding | Notes |

|---|---|---|---|---|

40000 |

MODEL_ID | R | u16 | e.g., 0x0430 (DIO-430) |

40001 |

FW_BUILD | R | YYYYMM | Snapshot / build tag |

40002 |

MB_ADDR | R/W | u16 | 1…255 |

40003 |

MB_BAUD | R/W | enum | 0=9600,1=19200,2=38400,3=57600,4=115200 |

40004 |

MB_PARITY | R/W | enum | 0=None,1=Even,2=Odd (default 0) |

6.4.2 Digital Inputs (per-channel)

Action codes: 0=None, 1=Toggle (latched), 2=Pulse (momentary)

Target codes: 4=None, 0=Control all, 1=R1, 2=R2, 3=R3

| Reg | Name | R/W | Encoding | Notes |

|---|---|---|---|---|

40010 |

DI_EN_MASK | R/W | bitmask | bit0…3 → IN1…IN4 enable |

40011 |

DI_INV_MASK | R/W | bitmask | bit0…3 → IN1…IN4 invert |

40012 |

DI1_ACTION | R/W | u16 enum | 0/1/2 |

40013 |

DI2_ACTION | R/W | u16 enum | 0/1/2 |

40014 |

DI3_ACTION | R/W | u16 enum | 0/1/2 |

40015 |

DI4_ACTION | R/W | u16 enum | 0/1/2 |

40016 |

DI1_TARGET | R/W | u16 enum | 4/0/1/2/3 |

40017 |

DI2_TARGET | R/W | u16 enum | 4/0/1/2/3 |

40018 |

DI3_TARGET | R/W | u16 enum | 4/0/1/2/3 |

40019 |

DI4_TARGET | R/W | u16 enum | 4/0/1/2/3 |

6.4.3 Relays / Buttons / LEDs

| Reg | Name | R/W | Encoding | Notes |

|---|---|---|---|---|

40020 |

RLY_EN_MASK | R/W | bitmask | bit0…2 → R1…R3 enable |

40021 |

RLY_INV_MASK | R/W | bitmask | invert coil logic (rarely used) |

40022 |

BTN1_ACTION | R/W | u16 enum | 0=None, 5=R1 toggle, 6=R2 toggle, 7=R3 toggle |

40023 |

BTN2_ACTION | R/W | u16 enum | as above |

40024 |

BTN3_ACTION | R/W | u16 enum | as above |

40025 |

LED_MODE | R/W | bit-packed | bits0…1 = LED1 (0=Steady,1=Blink), bits2…3 = LED2, bits4…5 = LED3 |

6.4.4 Status / Diagnostics

| Reg | Name | R/W | Encoding | Notes |

|---|---|---|---|---|

40030 |

UPTIME_S_LO | R | u16 | lower 16 bits |

40031 |

UPTIME_S_HI | R | u16 | upper 16 bits (32-bit seconds) |

40032 |

ERR_CODE | R | u16 | 0=OK; non-zero = last error |

40033 |

FLAGS | R | bitmask | e.g., cfg-dirty, wd-reset (implementation-specific) |

Note: All configuration is usually done via WebConfig. The registers above are provided to enable controller-side provisioning and telemetry when needed.

6.5 Input Registers (3x) — Convenience (Read-only)

| Reg | Name | Encoding | Description |

|---|---|---|---|

30000 |

DI_STATE_MASK | bitmask | bit0…3 → IN1…IN4 (post-invert) |

30001 |

RLY_STATE_MASK | bitmask | bit0…2 → R1…R3 |

30002 |

BTN_STATE_MASK | bitmask | bit0…2 → B1…B3 (momentary) |

30003 |

LED_STATE_MASK | bitmask | bit0…2 → LED1…LED3 active |

6.6 Register Use Examples

A) Toggle a relay from a PLC

- Write

1to Coil00001(R2_CMD) → Relay 2 ON - Write

0to the same coil → Relay 2 OFF

B) Map IN3 to drive Relay 1 as a latched toggle

40010 (DI_EN_MASK)→ set bit2 = 1 (enable IN3)40011 (DI_INV_MASK)→ set bit2 = 0 (no invert)40014 (DI3_ACTION)→ write1(Toggle)40018 (DI3_TARGET)→ write1(R1)

C) Set Button 2 to local override of Relay 2

40023 (BTN2_ACTION)→ write6(R2 toggle)

D) Make LED1 blink when Relay 1 is active

- In

40025 (LED_MODE): set LED1 field to Blink (value1)

E) Change Modbus address & baud from the master

40002 (MB_ADDR)→ new address (1…255)40003 (MB_BAUD)→ new enum (e.g.,1for 19200)- Coil

00010 (SAVE_CFG)= 1, then00011 (RESET)= 1

6.7 Polling Recommendations

- Transport: RS-485, daisy-chain, 120 Ω terminators at both ends, share COM/GND reference.

- Rates:

- States (1x/3x): 5–10 Hz typical (100–200 ms) for DI/relay/LED masks.

- Coils (0x): write only on change; read-after-write or echo via

RLY_STATE_MASK. - Holding (4x): configure at commissioning; read occasionally (e.g., every 5–10 s).

- Framing: Prefer 19200 8N1 for mixed networks; increase only on short, low-noise trunks.

- Time-outs/Retries: 100–250 ms timeout, 2–3 retries; back-off on bus errors.

- Edge logic: If a PLC supervises latching/timers, set DI Action = Pulse; if you want module-local latching, set Action = Toggle.

7. ESPHome Integration Guide (MiniPLC/MicroPLC + DIO-430-R1)

Support status: ✔️ Supported via ESPHome

uart+modbus+modbus_controllerand a reusable package.

Module role: Modbus RTU slave on RS-485.

Defaults: Address 3, 19200 8N1 (change in WebConfig).

7.1 Minimal YAML (Controller side)

Use this on the MiniPLC/MicroPLC (ESPHome). It enables the RS-485 bus and imports a ready-made DIO package.

uart:

id: uart_modbus

tx_pin: 17

rx_pin: 16

baud_rate: 19200

parity: NONE

stop_bits: 1

modbus:

id: modbus_bus

uart_id: uart_modbus

packages:

dio1:

url: https://github.com/isystemsautomation/HOMEMASTER

ref: main

files:

- path: DIO-430-R1/Firmware/default_dio_430_r1_plc/default_dio_430_r1_plc.yaml

vars:

dio_prefix: "DIO#1" # shown in Home Assistant entity names

dio_id: dio_1 # internal unique id

dio_address: 4 # Modbus address set in WebConfig for this DIO

refresh: 1d

For multiple DIOs, duplicate the

dio1:block (dio2:,dio3:…) with uniquedio_id,dio_prefix, anddio_address.

7.2 Entities exposed (from the package)

- Binary Sensors

- DI1…DI4 (post-invert, debounced)

- Switches

- Relay 1–3 (Modbus coils ON/OFF)

- Override ON/OFF for Relay 1–3 (forces state until released)

- Save Config / Soft Reset (commissioning helpers)

- Sensors (diagnostic)

- Button state mask (optional)

- LED state mask (optional)

- Uptime / flags (optional)

- Select/Number (optional, commissioning)

- Modbus address/baud view

- Per-input Enable/Invert/Action/Target (read/write helpers if enabled in the package)

The package sticks to the Modbus map defined in Section 6 (coils for relays, discrete inputs for DI states, holding/input registers for masks and configuration).

7.3 Optional: direct (manual) entity mapping

If you prefer not to use the package, you can expose the core points directly:

modbus_controller:

- id: dio430_4

address: 4

modbus_id: modbus_bus

update_interval: 200ms

command_throttle: 100ms

binary_sensor:

# DI1..DI4 as Discrete Inputs (1x offsets 0..3)

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 DI1"

register_type: discrete_input

address: 0

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 DI2"

register_type: discrete_input

address: 1

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 DI3"

register_type: discrete_input

address: 2

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 DI4"

register_type: discrete_input

address: 3

switch:

# Relays as Coils (0x offsets 0..2)

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 Relay 1"

register_type: coil

address: 0

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 Relay 2"

register_type: coil

address: 1

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 Relay 3"

register_type: coil

address: 2

sensor:

# (Optional) LED and Button masks from Input Registers 30003/30002

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 LED Mask"

register_type: input

address: 3

value_type: U_WORD

accuracy_decimals: 0

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 Button Mask"

register_type: input

address: 2

value_type: U_WORD

accuracy_decimals: 0

7.4 Home Assistant tips (dashboards & automations)

- Dashboards

- Lighting panel: Card for Relay 1–3 plus DI tiles (e.g., wall switch/sensor feedback).

- Maintenance card: Override ON/OFF for each relay + Reset Device + Save Config.

- Automations

- DI → Relay: If you keep the logic in HA/PLC (instead of module mapping), trigger relay switches when a DI goes high.

- Night mode: When

input_boolean.night_modeis on, force a specific Override ON and release it in the morning.

- Naming

- Use

dio_prefixto keep entities readable (DIO#1 Relay 1,DIO#2 DI3, etc.).

- Use

7.5 Troubleshooting

- No response / timeouts: check A/B polarity, shared COM/GND reference, and 120 Ω termination at bus ends.

- Wrong device: make sure

dio_addressin the package matches the WebConfig address. - Relays don’t switch: ensure the relay is Enabled in WebConfig and not “held” by an Override.

- DI not changing: verify wiring to INx/GNDx (respect isolation); check Invert/Enable/Action/Target in WebConfig.

7.7 Notes & Versions

- Works with recent ESPHome releases (e.g., 2025.x).

- Keep

update_intervalmodest (e.g., 200–500 ms) unless you need faster DI polling. - For multiple devices on one bus, stagger

update_interval/command_throttleto reduce collisions.

8. Programming & Customization (DIO-430-R1)

8.1 Supported Languages

- Arduino

- C++ (PlatformIO)

- MicroPython (community builds for RP23xx-class MCUs)

8.2 Flashing (USB‑C, Hardware Buttons Only)

The module exposes a USB device for flashing. All reset/boot actions are done with the front buttons in hardware.

Button layout (front panel):

Combinations

- 2 + 3 → BOOT mode (enter bootloader for flashing)

- 1 + 3 → RESET (hardware reset/restart)

Steps (UF2/IDE)

- Connect USB‑C to a PC (disconnect RS‑485 during flashing).

- Hold Buttons 2 + 3 to enter BOOT. The board appears as a USB drive (UF2) or a serial device for IDE upload.

- Flash:

- UF2: drag‑and‑drop the new

.uf2file onto the mounted drive; the module restarts automatically. - PlatformIO / Arduino IDE: select the correct board/port and upload.

- UF2: drag‑and‑drop the new

- If needed, press Buttons 1 + 3 for a hardware RESET.

No factory‑reset function is provided. Configuration remains intact across normal firmware updates.

8.3 Arduino / PlatformIO Notes

Board / Toolchain

- Board: Generic RP2350 (or vendor core for RP2350A)

- USB: CDC enabled (serial logging)

- FS: LittleFS partition recommended (for settings)

Required Libraries (typical firmware)

ModbusSerial(or equivalent RTU)Arduino_JSONLittleFSSimpleWebSerial(or equivalent transport for WebConfig)Wire(I²C; if using expanders in forks)

Pin Mapping (DIO-430-R1 default firmware)

- Relays: R1=GPIO10, R2=GPIO9, R3=GPIO8 (active‑HIGH)

- Digital Inputs: IN1=GPIO6, IN2=GPIO11, IN3=GPIO12, IN4=GPIO7 (processed with enable/invert/debounce in firmware)

- Buttons: B1=GPIO1, B2=GPIO2, B3=GPIO3 (active‑LOW)

- User LEDs: L1=GPIO13, L2=GPIO14, L3=GPIO15 (active‑HIGH)

- RS‑485 (UART): TX=GPIO4, RX=GPIO5 (DE/RE handled in software)

Build Tips

- Start at 19200 8N1 on RS‑485 during bring‑up.

- After flashing, disconnect USB‑C and return control to the master on RS‑485.

8.4 Firmware Updates

- Method: USB‑C via UF2 drag‑drop or PlatformIO/Arduino upload.

- Config retention: Settings stored in flash/LittleFS are preserved unless explicitly erased.

- Recovery: If the app doesn’t start, use Buttons 2 + 3 to force BOOT, then re‑flash. Use Buttons 1 + 3 for a hardware RESET after flashing.

9. Maintenance & Troubleshooting

9.1 Status LEDs (typical)

- PWR — ON in normal operation

- TX/RX — blink on Modbus traffic

- User LEDs (1–3) — follow relay logic (Steady/Blink based on WebConfig mode)

9.2 Resets

- Power cycle: remove 24 V, wait 5 s, re‑apply

- Use Buttons 1 + 3 for a hardware RESET

9.3 Common Issues

| Symptom | Checks |

|---|---|

| No Modbus comms | A/B polarity, COM/GND reference, 120 Ω termination, address/baud match, only two end terminators |

| Relays don’t actuate | Relay Enabled in WebConfig, no active Override holding state, coil invert setting, Modbus coil writes acknowledged |

| DI not changing | Wire to INx/GNDx (isolated field side), check Enable/Invert/Action/Target in WebConfig, debounce expectations |

| USB won’t connect | Chrome/Edge with Web Serial, close other serial apps, check cable/port permissions |

| Config not saved | Allow idle for auto‑save or use Save if available; verify LittleFS space |

10. Open Source & Licensing

- Hardware: CERN‑OHL‑W v2

- Firmware: GPLv3

- Config Tools (WebConfig UI): MIT (unless folder states otherwise)

See the repository LICENSE files for the exact texts and sub‑component licenses.

11. Downloads

- Firmware binaries

- YAML configs (ESPHome)

- Package & examples:

DIO-430-R1/Firmware/default_dio_430_r1_plc/

- Package & examples:

- WebConfig tool (HTML/JS)

- Schematics (PDF)

- Field Board:

Schematics/DIO-430-R1-FieldBoard.pdf - MCU Board:

Schematics/DIO-430-R1-MCUBoard.pdf

- Field Board:

- Images & diagrams

- Datasheets

- Refer to the

Schematics/folder BOM notes for part numbers (e.g., ISO1212, MAX485, HF115F).

- Refer to the

12. Support

- Official Support Portal: https://www.home-master.eu/support

- WebConfig Tool: https://www.home-master.eu/configtool-dio-430-r1

- YouTube: https://youtube.com/@HomeMaster

- Hackster: https://hackster.io/homemaster

- Reddit: https://reddit.com/r/HomeMaster

- Instagram: https://instagram.com/home_master.eu

DIO-430-R1 — Module for Smart I/O Control

HOMEMASTER – Modular control. Custom logic.

1. Introduction

The DIO-430-R1 is a configurable smart digital I/O module designed for digital input monitoring and relay-based output control in building automation, lighting, HVAC, alarms, and general control systems.

It offers 4 opto-isolated digital inputs, 3 high-current SPDT relays, 3 user buttons, and 3 configurable user LEDs. All I/O channels are individually configurable, allowing flexible logic such as toggle, pulse, manual override, and alarm indication.

It connects via RS-485 (Modbus RTU) to a MicroPLC, MiniPLC, or any compatible controller, and can also integrate with Home Assistant (ESPHome) or SCADA/PLC systems.

Configuration and diagnostics are performed through a driverless Web Serial interface via USB-C, using the browser-based WebConfig Tool. The module supports both master-controlled and standalone local logic modes.

| Subsystem | Qty | Description |

|---|---|---|

| Digital Inputs | 4 | Opto-isolated, dry contact compatible, noise-protected |

| Relays | 3 | SPDT (NO/NC), 16 A rated, dry contacts |

| LEDs | 3 | Configurable: Steady or Blink modes, linked to relays |

| Buttons | 3 | User-configurable for override or reset |

| Modbus RTU | Yes | RS-485 interface (Configurable: Addr 1–255, 9600–115200 baud) |

| USB-C | Yes | WebConfig tool access via Web Serial (Chrome/Edge) |

| Power | 24 V DC | Fused input, reverse-polarity and surge protected |

| MCU | RP2350 | Dual-core, with QSPI flash, USB, UART, LittleFS |

| Protection | TVS, PTC | ESD, surge, and short-circuit protection on I/O and power |

System Role & Communication

The module communicates over the RS-485 Modbus RTU bus, using A/B differential lines and a shared COM/GND reference. It supports poll-based communication, where a master device reads input states and writes relay commands.

All configuration — including input-to-relay mapping, LED modes, and button logic — is stored persistently in internal flash via LittleFS and can be changed live through USB-C + WebConfig.

Factory default communication settings:

- Modbus Address:

3 - Baud Rate:

19200 - Parity:

None - Stop Bits:

1

The module’s logic (input→relay mapping, LED modes, button behavior) is stored persistently in internal flash via LittleFS, and settings can be changed live using USB-C + WebConfig.

2. DIO-430-R1 — Technical Specification

2.1 Diagrams & Pinouts

System overview, board callouts, and pin mapping:

2.2 I/O and Electrical Summary

| Interface | Qty | Description |

|---|---|---|

| Digital Inputs | 4 | Galvanically isolated (ISO1212 class). Supports dry contacts or 24 V signals. PTC + TVS per channel. |

| Relay Outputs | 3 | SPDT (NO/NC/COM), 16 A dry contacts. Use RC/MOV snubbers or interposing contactors for inductive/mains loads. |

| User LEDs | 3 | Configurable (Steady/Blink). Follow relay or logic status. |

| Buttons | 3 | Momentary. Configurable for relay override/toggle. |

| RS-485 (Modbus RTU) | 1 | A/B/COM terminals. Daisy-chain topology. 120 Ω termination at both ends. |

| USB-C | 1 | Web Serial setup, diagnostics, and firmware flashing (ESD-protected). |

| Power Input | 1 | 24 V DC SELV. Reverse-polarity + surge protected. |

Electrical Ratings

| Parameter | Min | Typ | Max | Unit | Notes |

|---|---|---|---|---|---|

| Supply Voltage | 22 | 24 | 28 | V DC | SELV/PELV input |

| Logic Consumption | – | 1.5 | 3.0 | W | Excludes relay loads |

| Digital Input Range | 0 | 24 | 30 | V DC | Isolated, noise-protected |

| Relay Contact Current | – | – | 16 | A | SPDT dry contacts |

| Relay Contact Voltage | – | – | 250 | V AC | or 30 V DC max |

| RS-485 Data Rate | – | 19.2 | 115.2 | kbps | Default 19200 8N1 |

| USB-C Voltage | 4.75 | 5.0 | 5.25 | V DC | Service only |

| Operating Temp. | 0 | – | 40 | °C | ≤ 95 % RH, non-condensing |

Power budgeting: logic + LEDs + up to 3 relay coils + sensor loads → add ≥ 30 % PSU headroom.

2.3 Connectors & Terminal Map

| Block | Pins | Function | Notes |

|---|---|---|---|

| POWER | 0V, V+ | 24 V DC input | Reverse/surge protected |

| RELAY 1-3 | NO, C, NC | SPDT contacts | Add RC/MOV for inductive loads |

| DI 1-4 | INx, GNDx | Isolated digital inputs | 24 V field or dry contact |

| RS-485 | B, A, COM | Modbus RTU bus | Terminate 120 Ω at ends |

| USB-C | D+, D−, VBUS, GND | Setup / Service port | Not for field powering |

2.4 Reliability & Protection

- Reverse-path diode + high-side MOSFET on 24 V input.

- Local PTC + TVS protection on field interfaces.

- Relay drivers opto-isolated; RC/MOV suppression recommended.

- RS-485 with TVS, series protection, and fail-safe biasing.

- USB-C ESD-protected; CC resistors per spec.

- Non-volatile flash with auto-save after configuration changes.

2.5 Functional Overview

- Modbus RTU slave (factory Addr 3, 19200 8N1; configurable 1–255, 9600–115200).

- Inputs → Relays: per-input Enable/Invert/Action (

None/Toggle/Pulse) and Target (R1–R3orAll). - Buttons: assignable to relay override (toggle).

- LEDs: configurable Steady/Blink following relay status.

- Setup via WebConfig: USB-C → Chrome/Edge; set comms and I/O mapping.

- Persistent config: stored in LittleFS and restored on boot.

2.6 Mechanical & Environmental

| Property | Specification |

|---|---|

| Mounting | DIN-rail EN 50022 (35 mm) |

| Enclosure | PC/ABS V-0, panel mount |

| Dimensions | 70 × 90.6 × 67.3 mm (W × H × D) |

| Terminals | Pluggable 5.08 mm, 26–12 AWG (≤ 2.5 mm²), 0.5–0.6 Nm |

| Ingress Protection | IP20 (panel interior) |

| Operating Temp | 0–40 °C, ≤ 95 % RH (non-condensing) |

2.7 Standards & Compliance

| Standard / Directive | Description |

|---|---|

| Ingress Rating | IP20 (panel-mount only) |

| Altitude | ≤ 2000 m |

| Environmental | RoHS / REACH compliant components |

3. Use Cases

The DIO‑430‑R1 supports both lighting and motor/pump control — making it ideal for mixed automation tasks in smart homes, greenhouses, HVAC, and industrial setups.

Below are 3 versatile examples combining both types of loads.

3.1 Staircase Light with Motion Sensor + Circulation Pump

Automatically turns ON a staircase light and a circulation pump when motion is detected.

Setup Instructions:

- Set IN1 to

Action = Pulse,Target = Relay 1(light). - Set IN2 to

Action = Pulse,Target = Relay 2(pump). - Enable Relay 1 for the staircase lighting.

- Enable Relay 2 for the circulation pump.

- Set LED 1 =

Blink, source =Relay 1. - Set LED 2 =

Steady, source =Relay 2.

3.2 Manual Light + Fan Override (Wall Panel)

Wall-mounted buttons allow users to toggle lights and exhaust fans independently.

Setup Instructions:

- Assign Button 1 →

Relay 1 override (toggle)→ Room Light - Assign Button 2 →

Relay 2 override (toggle)→ Ventilation Fan - Enable both Relay 1 and Relay 2.

- Set LED 1 and LED 2 to

Steady, following respective relays. - Optionally use Modbus Coils

200–201for remote control.

3.3 Greenhouse Light + Irrigation Pump Automation

Lights and irrigation are controlled via digital inputs or remotely from a PLC.

Setup Instructions:

- IN3 →

Toggle, Target =Relay 1→ Grow Light - IN4 →

Pulse, Target =Relay 2→ Irrigation Pump - Enable Relay 1 and Relay 2.

- Assign Button 3 to

Relay 2 override (toggle)for manual watering. - Set LED 1 =

Steady(light status), LED 2 =Blink(pump running).

4. Safety Information

These guidelines apply to the DIO-430-R1 I/O module. Ignoring them may result in equipment damage, system failure, or personal injury.

⚠️ SELV/PELV Domains Only

- The DIO-430-R1 operates entirely within SELV/PELV low-voltage domains (e.g., 24 V DC, RS-485, USB 5 V).

- Do not connect mains voltage to any terminal. Use interposing contactors/PSUs for mains loads.

- Respect isolation boundaries: never bridge logic GND with isolated field grounds (e.g., GND_ISO / FGND).

- Connect sensor returns only to the isolated field ground; connect RS-485 COM/GND only within the same SELV domain.

4.1 General Requirements

| Requirement | Detail |

|---|---|

| Qualified Personnel | Installation and servicing must be done by qualified personnel familiar with 24 V control systems and RS-485. |

| Power Isolation | Disconnect the 24 V DC input before wiring. Lockout/tagout where applicable. |

| Environmental Limits | Mount in a clean, sealed enclosure; avoid condensation, conductive dust, or vibration. |

| Grounding | Bond the panel to PE. Keep RS-485 COM/GND shared with the controller side. |

| Voltage Compliance | SELV only on all terminals. Follow relay contact ratings on the product label/datasheet. Use upstream fusing and surge protection. |

4.2 Installation Practices

| Task | Guidance |

|---|---|

| ESD Protection | Handle by the enclosure/edge only. Use an antistatic wrist strap when the board is exposed. |

| DIN Rail Mounting | Mount securely on 35 mm DIN rail inside an IP-rated cabinet. Leave cable slack for strain relief. |

| Wiring | Use correct wire gauge and torque terminal screws. Separate power, DI, relay, and RS-485 harnesses. |

| Isolation Domains | Respect isolation: do not bridge logic GND to isolated field grounds (e.g., GND_ISO/FGND). Keep analog/sensor returns on the isolated side. |

| Commissioning | Before power-up, verify polarity, relay NO/NC routing, RS-485 A/B orientation and termination. |

4.3 I/O & Interface Warnings

🔌 Power

| Area | Warning |

|---|---|

| 24 V DC Input | Use a clean, fused SELV supply. Reverse-polarity protection exists but may disable the module when triggered. |

| Sensor Rail | Power sensors from a SELV rail. Observe polarity. Fuse external branches as required. |

| Surge/Noise | In noisy panels, add upstream surge/EMI suppression and keep high-current wiring away from control wiring. |

⏽ Inputs (Digital)

| Area | Warning |

|---|---|

| Type | Dry contact / 24 V signaling only, per your standard. Do not inject mains or undefined levels. |

| Isolation | Inputs are isolated from logic. Keep sensor returns on the field/isolated domain; do not bond to logic GND. |

| Debounce | Firmware provides debounce, but route away from contactors/VFDs and use shielded/twisted pairs for long runs. |

| Polarity | Configure invert/action in WebConfig; verify state transitions after wiring. |

⚙️ Relays (Outputs)

| Area | Warning |

|---|---|

| Contact Type | SPDT (NO/NC/COM) dry contacts. Follow the contact rating on the device label/datasheet. |

| Inductive Loads | For motors/solenoids/contactors, add an RC snubber or MOV at the load. Consider interposing relays/ contactors for higher power. |

| Separation | Keep relay load wiring physically separate from signal wiring. De-energize before servicing. |

| Verification | After wiring, verify NO/NC behavior and load polarity before enabling automation. |

🖧 RS-485 (Modbus RTU)

| Area | Warning |

|---|---|

| Topology | Use twisted pair; daisy-chain (no stubs). Terminate with 120 Ω at both physical ends. |

| Polarity | Maintain A/B polarity consistently. Share COM/GND reference between nodes (same SELV domain). |

| EMC | Route away from VFDs, contactors, and mains bundles. Use shielded cable in high-EMI environments. |

| Protection | Port includes protection, but good wiring practice is still required to avoid transients. |

🔌 USB-C (Front / Setup)

| Area | Warning |

|---|---|

| Purpose | Setup & maintenance only (WebConfig / firmware). Not intended for powering field devices. |

| ESD/EMI | Avoid hot-plugging in high-EMI areas. Use a grounded service laptop. Disconnect after commissioning. |

🔆 Front Panel (Buttons & LEDs)

| Area | Warning |

|---|---|

| Buttons & LEDs | Buttons can override relays; document operating procedures. Lock out overrides for safety-critical installs. |

🛡️ Shielding & EMC

| Area | Recommendation |

|---|---|

| Cable Shields | Terminate shields at one end (typically the PLC/controller). Keep runs short and away from high-voltage/EMI sources. |

✅ Pre-Power Checklist

- No bridge between logic GND and isolated GND_ISO/FGND

- A/B polarity and 120 Ω termination confirmed at bus ends

- not exceed the contact rating; snubbers added for inductive loads

- dry contact/SELV only; sensor polarity and returns verified

5. Installation & Quick Start

The DIO-430-R1 joins your system over RS-485 (Modbus RTU). Setup has two parts:

- Physical wiring, 2) Digital configuration (WebConfig → optional PLC/ESPHome).

5.1 What You Need

| Category | Item / Notes |

|---|---|

| Hardware | DIO-430-R1 — DIN-rail module with 4× DI, 3× SPDT relays, 3× buttons, 3× LEDs, USB-C, RS-485. |

| Controller (master) | HomeMaster MiniPLC/MicroPLC or any Modbus RTU master. |

| 24 VDC PSU (SELV) | Regulated 24 VDC; size for logic + relay coils + sensors; inline panel fuse/breaker. Power input stage includes fuse/TVS/reverse-polarity protection. |

| RS-485 cable | Twisted pair for A/B + COM/GND reference, 120 Ω termination at both ends of the trunk. |

| USB-C cable | For WebConfig via a Chromium browser (service/commissioning). |

| Software | Chromium-based browser with Web Serial (Chrome/Edge). Web page exposes Address/Baud + I/O mapping. |

| Field I/O | Dry contacts to DI1…DI4 (isolated front-end per channel). Relays (NO/NC/COM) drive LV loads or interposing contactors; add RC/MOV snubbers for inductive loads. |

Quick path: mount → wire 24 VDC + RS-485 A/B/COM → connect USB-C → WebConfig: set Address/Baud + map inputs → relays/LEDs → disconnect USB → hand over to controller.

5.2 Power

The module uses 24 VDC primary. Onboard regulation provides 5 V → 3.3 V for logic; DI front-end is isolated.

5.2.1 Supply Types

- 24 VDC DIN-rail PSU → 24Vdc(+) / 0V(–) power terminals (top row: POWER).

- Sensor side (DI) — isolated input receivers accept field signals; feed your sensors from the 24 V field rail and return to the DI GND pins (per-channel). Do not back-power logic from sensor rails.

5.2.2 Sizing (rule of thumb)

Account for:

- Base electronics + LEDs

- Relay coils (up to 3 simultaneously)

- Sensor rails (DI field side, if powered from the same 24 V source)

Size PSU for worst-case relays + sensors, then add ≥30 % headroom.

5.2.3 Power Safety

- Correct polarity; keep logic GND and DI field ground separate (respect isolation domains).

- Keep upstream fusing/breaker in place; the board also has input fuse/TVS/reverse-polarity MOSFET.

- Use snubbers on inductive loads; prefer interposing contactors for motors/pumps.

- De-energize before wiring; check shorts before power-up.

5.3 Networking & Communication

Runtime control is via RS-485 (Modbus RTU). USB-C is for local setup/diagnostics (Web Serial).

5.3.1 RS-485 (Modbus RTU)

Physical

- Terminals (lower front row): B, A, COM/GND → then DI and DI-GNDs. Maintain A/B polarity, share the COM/GND reference with the controller.

- Cable: Twisted pair (preferably shielded) for A/B + reference.

- Termination: 120 Ω at both physical ends of the trunk; avoid stubs.

Protocol

- Role: RTU slave; controller is master.

- Address: 1–255. Factory default: Address 3, 19200 8N1.

- Required: Dedicated 24 VDC power (bus is data-only).

Checklist

- A→A, B→B, COM→COM (GND ref).

- Two end terminations only; daisy-chain topology.

- Consistent A/B polarity end-to-end.

5.3.2 USB-C (WebConfig)

Purpose: Chromium (Chrome/Edge) Web Serial setup/diagnostics page.

Steps

- Connect USB-C to the module.

- Open the DIO-430-R1 WebConfig page and click Connect.

- Set Modbus Address & Baud (header shows Active Modbus Configuration).

- Configure Inputs / Relays / LEDs / Buttons; changes apply live and are saved to flash.

- Use Reset Device from the page if needed (dialog confirms).

If Connect is disabled: ensure Chromium + serial permission; close other apps that might hold the port.

5.4 Installation & Wiring

This section shows typical wiring for power, inputs, relays, RS-485, and the USB-C service port.

⚠️ Work on de-energized equipment only. Use SELV/PELV supplies for logic and field inputs. Mains on relay contacts must be wired by qualified personnel.

A) Power — 24 VDC (SELV)

Wire the regulated 24 VDC supply to the top POWER terminals: V+ and 0V.

Notes

- Keep V+/0V as a twisted pair; route away from motor cables/contactors.

- The module includes input protection (fuse/TVS/reverse-polarity MOSFET).

B) Digital Inputs (DI1…DI4)

Each input is isolated. Land the contact/sensor on INx with the paired GNDx return.

Tips

- Supports dry contacts or compatible 24 V field signals.

- Configure in WebConfig: Enabled/Invert, Action (

None / Toggle / Pulse), Control target (None / All / R1 / R2 / R3). - Keep field wiring shielded/twisted for long runs; terminate shield at one end only.

C) Relay Outputs (R1…R3)

Relays provide dry SPDT contacts (NO/NC/COM) for switching low-voltage loads or driving an interposing contactor for mains/inductive loads.

Best practices

- Add RC/MOV snubbers across inductive loads (fans, pumps, contactors).

- Keep load and logic wiring separated; observe conductor ratings and local code.

D) Sensor Rails (12 V / 5 V)

This module does not export auxiliary 12 V/5 V rails for field devices.

- Power sensors from your panel 24 V rail (or external rails as required).

- Return sensor commons to the matching DI GNDx terminals; do not bond field ground to logic GND.

E) RS-485 (Modbus RTU)

The lower left terminals expose B, A, and COM (GND). Use shielded twisted pair and daisy-chain topology.

Checklist

- Wire A→A, B→B, and share COM/GND with the controller.

- Terminate the two physical bus ends with 120 Ω.

- Default protocol: Address 3, 19200 8N1 (change via WebConfig).

F) USB-C (Service / WebConfig)

- Use USB-C for commissioning and diagnostics only (Web Serial in Chrome/Edge).

- Not for powering field devices. Disconnect after setup and hand control to the RS-485 master.

5.5 Software & UI Configuration

Use the WebConfig page (USB-C + Chrome/Edge) to set Modbus comms and map I/O. Changes apply immediately and are saved to flash.

Screens shown below are from the DIO-430-R1 WebConfig.

A) WebConfig setup (Address & Baud)

- Connect the module via USB-C → open the WebConfig page → click Connect.

- In Modbus Address, choose 1–255 (factory default 3).

- In Baud Rate, select 9600–115200 (factory default 19200 8N1).

- Confirm the Active Modbus Configuration banner updates (Address/Baud).

Default values (Addr 3, 19200 8N1) are also noted in the module docs.

B) Inputs — enable / invert / group (control target)

Each IN1…IN4 card provides:

- Enabled: include the input in logic.

- Inverted: logical inversion.

- Action:

None / Toggle / Pulse. - Control target:

None / Control all / Relay 1 / Relay 2 / Relay 3.

This matches the firmware’s input options and allows direct mapping from inputs to one or more relays without a PLC.

Tips

- Use Toggle to latch a relay on each press; Pulse for momentary actions (timers handled by controller if needed).

- For “group” behavior, select Control all to operate Relays 1–3 together.

C) Relays — logic mode (group/manual)

For Relay 1–3:

- Enabled: relay is controllable.

- Inverted: invert drive polarity (use only if required by wiring).

Logic modes in practice

- Group control: Achieve via Input Control target = Control all (see Inputs section).

- Manual / local override: Assign Buttons (below) to toggle a specific relay even when the PLC also controls it.

D) LED and Button mapping

Buttons (3)

- Action: choose

Noneor Relay override (toggle) for Relay 1/2/3. This provides local/manual control without a PLC.

User LEDs (3)

- Mode:

SteadyorBlink(active when source is ON). - Activate when: select the source relay to follow (e.g., LED1 foll

5.6 Getting Started (3 Phases)

Phase 1 — Wire

- 24 VDC to V+ / 0V (GND) (top POWER terminals)

Use a regulated SELV supply; keep pairs twisted. - Digital inputs (IN1–IN4): dry contacts → INx / GNDx

Respect isolation domains; do not bridge logic GND ↔ field GND. - Relay outputs (R1–R3): COM / NO / NC

Prefer interposing contactors for motors/pumps; add RC/MOV snubber on inductive loads. - RS-485: A / B / COM (GND)

Shielded twisted pair; daisy-chain; terminate bus ends with 120 Ω. - USB-C (service): for WebConfig only (no field powering).

👉 See: Installation & Quick Start

Phase 2 — Configure (WebConfig)

- Open

https://www.home-master.eu/configtool-dio-430-r1in Chrome/Edge. - Connect USB-C → Select port → Connect.

- Set:

- Modbus Address / Baud (default: Addr 3, 19200 8N1)

- Inputs: Enable / Invert / Action (

None / Toggle / Pulse) / Control target (None / All / R1 / R2 / R3) - Relays: Enable (optional Invert)

- Buttons: map to Relay override (toggle) (R1/R2/R3)

- User LEDs: Mode (

Steady / Blink) + Activate when (follow a relay)

- Click Reset Device if prompted; settings auto-save to flash.

👉 See: WebConfig UI

Phase 3 — Integrate (Controller)

- Connect controller (MiniPLC/MicroPLC/PLC/SCADA/ESPHome) via RS-485.

- Match address and baud.

- Poll:

- Discrete inputs for DI states and relay states (per your mapping)

- Write:

- Coils to control relays (e.g., R1/R2/R3 ON/OFF)

- Use with:

- HomeMaster MicroPLC / MiniPLC

- ESPHome / SCADA / PLC

👉 See: Modbus RTU Communication & Integration Guide

✅ Verify

| Area | What to Check |

|---|---|

| LEDs | PWR = ON; TX/RX blink during RS-485 traffic |

| Inputs | Toggling a wall switch/sensor changes INx state in WebConfig/Modbus |

| Relays | Coil writes toggle R1–R3; loads switch correctly; snubber installed for inductive loads |

| Address/Baud | Controller reads module at the configured address/baud without errors |

| Isolation | No unintended bond between logic GND and DI field GNDx |

6. Modbus RTU Communication

Role: RTU slave (controller is master)

Defaults: Address 3, 19200 8N1 (change in WebConfig → Modbus)

Addressing shown below uses zero-based offsets (e.g., Holding Reg

40000= offset0).

If your master uses 1-based display (e.g., 40001), add +1 to the register number.

6.1 Address Range & Map (Overview)

| Type | Range (offsets) | Purpose |

|---|---|---|

| Coils (0x) | 00000…00031 |

Relay commands, device control |

| Discrete Inputs (1x) | 10000…10031 |

DI states, relay echo states |

| Input Registers (3x) | 30000…30031 |

Read-only status (masks, counters) |

| Holding Registers (4x) | 40000…40063 |

Config & runtime parameters (DI actions/targets, relay/LED/button settings, comms) |

6.2 Coils (0x) — Commands

| Coil | Name | Description |

|---|---|---|

00000 |

R1_CMD | Relay 1 ON/OFF (write 1/0) |

00001 |

R2_CMD | Relay 2 ON/OFF |

00002 |

R3_CMD | Relay 3 ON/OFF |

00010 |

SAVE_CFG | Persist current settings to flash (write 1) |

00011 |

RESET | Soft reset device (write 1) |

Coils drive relays regardless of input mappings (local buttons still work as overrides).

6.3 Discrete Inputs (1x) — States

| DI | Name | Description |

|---|---|---|

10000 |

DI1_STATE | Digital Input 1 (after invert option) |

10001 |

DI2_STATE | Digital Input 2 |

10002 |

DI3_STATE | Digital Input 3 |

10003 |

DI4_STATE | Digital Input 4 |

10010 |

R1_STATE | Relay 1 actual state (echo) |

10011 |

R2_STATE | Relay 2 actual state |

10012 |

R3_STATE | Relay 3 actual state |

6.4 Holding Registers (4x) — Configuration & Runtime

6.4.1 Identity / Comms

| Reg | Name | R/W | Encoding | Notes |

|---|---|---|---|---|

40000 |

MODEL_ID | R | u16 | e.g., 0x0430 (DIO-430) |

40001 |

FW_BUILD | R | YYYYMM | Snapshot / build tag |

40002 |

MB_ADDR | R/W | u16 | 1…255 |

40003 |

MB_BAUD | R/W | enum | 0=9600,1=19200,2=38400,3=57600,4=115200 |

40004 |

MB_PARITY | R/W | enum | 0=None,1=Even,2=Odd (default 0) |

6.4.2 Digital Inputs (per-channel)

Action codes: 0=None, 1=Toggle (latched), 2=Pulse (momentary)

Target codes: 4=None, 0=Control all, 1=R1, 2=R2, 3=R3

| Reg | Name | R/W | Encoding | Notes |

|---|---|---|---|---|

40010 |

DI_EN_MASK | R/W | bitmask | bit0…3 → IN1…IN4 enable |

40011 |

DI_INV_MASK | R/W | bitmask | bit0…3 → IN1…IN4 invert |

40012 |

DI1_ACTION | R/W | u16 enum | 0/1/2 |

40013 |

DI2_ACTION | R/W | u16 enum | 0/1/2 |

40014 |

DI3_ACTION | R/W | u16 enum | 0/1/2 |

40015 |

DI4_ACTION | R/W | u16 enum | 0/1/2 |

40016 |

DI1_TARGET | R/W | u16 enum | 4/0/1/2/3 |

40017 |

DI2_TARGET | R/W | u16 enum | 4/0/1/2/3 |

40018 |

DI3_TARGET | R/W | u16 enum | 4/0/1/2/3 |

40019 |

DI4_TARGET | R/W | u16 enum | 4/0/1/2/3 |

6.4.3 Relays / Buttons / LEDs

| Reg | Name | R/W | Encoding | Notes |

|---|---|---|---|---|

40020 |

RLY_EN_MASK | R/W | bitmask | bit0…2 → R1…R3 enable |

40021 |

RLY_INV_MASK | R/W | bitmask | invert coil logic (rarely used) |

40022 |

BTN1_ACTION | R/W | u16 enum | 0=None, 5=R1 toggle, 6=R2 toggle, 7=R3 toggle |

40023 |

BTN2_ACTION | R/W | u16 enum | as above |

40024 |

BTN3_ACTION | R/W | u16 enum | as above |

40025 |

LED_MODE | R/W | bit-packed | bits0…1 = LED1 (0=Steady,1=Blink), bits2…3 = LED2, bits4…5 = LED3 |

6.4.4 Status / Diagnostics

| Reg | Name | R/W | Encoding | Notes |

|---|---|---|---|---|

40030 |

UPTIME_S_LO | R | u16 | lower 16 bits |

40031 |

UPTIME_S_HI | R | u16 | upper 16 bits (32-bit seconds) |

40032 |

ERR_CODE | R | u16 | 0=OK; non-zero = last error |

40033 |

FLAGS | R | bitmask | e.g., cfg-dirty, wd-reset (implementation-specific) |

Note: All configuration is usually done via WebConfig. The registers above are provided to enable controller-side provisioning and telemetry when needed.

6.5 Input Registers (3x) — Convenience (Read-only)

| Reg | Name | Encoding | Description |

|---|---|---|---|

30000 |

DI_STATE_MASK | bitmask | bit0…3 → IN1…IN4 (post-invert) |

30001 |

RLY_STATE_MASK | bitmask | bit0…2 → R1…R3 |

30002 |

BTN_STATE_MASK | bitmask | bit0…2 → B1…B3 (momentary) |

30003 |

LED_STATE_MASK | bitmask | bit0…2 → LED1…LED3 active |

6.6 Register Use Examples

A) Toggle a relay from a PLC

- Write

1to Coil00001(R2_CMD) → Relay 2 ON - Write

0to the same coil → Relay 2 OFF

B) Map IN3 to drive Relay 1 as a latched toggle

40010 (DI_EN_MASK)→ set bit2 = 1 (enable IN3)40011 (DI_INV_MASK)→ set bit2 = 0 (no invert)40014 (DI3_ACTION)→ write1(Toggle)40018 (DI3_TARGET)→ write1(R1)

C) Set Button 2 to local override of Relay 2

40023 (BTN2_ACTION)→ write6(R2 toggle)

D) Make LED1 blink when Relay 1 is active

- In

40025 (LED_MODE): set LED1 field to Blink (value1)

E) Change Modbus address & baud from the master

40002 (MB_ADDR)→ new address (1…255)40003 (MB_BAUD)→ new enum (e.g.,1for 19200)- Coil

00010 (SAVE_CFG)= 1, then00011 (RESET)= 1

6.7 Polling Recommendations

- Transport: RS-485, daisy-chain, 120 Ω terminators at both ends, share COM/GND reference.

- Rates:

- States (1x/3x): 5–10 Hz typical (100–200 ms) for DI/relay/LED masks.

- Coils (0x): write only on change; read-after-write or echo via

RLY_STATE_MASK. - Holding (4x): configure at commissioning; read occasionally (e.g., every 5–10 s).

- Framing: Prefer 19200 8N1 for mixed networks; increase only on short, low-noise trunks.

- Time-outs/Retries: 100–250 ms timeout, 2–3 retries; back-off on bus errors.

- Edge logic: If a PLC supervises latching/timers, set DI Action = Pulse; if you want module-local latching, set Action = Toggle.

7. ESPHome Integration Guide (MiniPLC/MicroPLC + DIO-430-R1)

Support status: ✔️ Supported via ESPHome

uart+modbus+modbus_controllerand a reusable package.

Module role: Modbus RTU slave on RS-485.

Defaults: Address 3, 19200 8N1 (change in WebConfig).

7.1 Minimal YAML (Controller side)

Use this on the MiniPLC/MicroPLC (ESPHome). It enables the RS-485 bus and imports a ready-made DIO package.

uart:

id: uart_modbus

tx_pin: 17

rx_pin: 16

baud_rate: 19200

parity: NONE

stop_bits: 1

modbus:

id: modbus_bus

uart_id: uart_modbus

packages:

dio1:

url: https://github.com/isystemsautomation/HOMEMASTER

ref: main

files:

- path: DIO-430-R1/Firmware/default_dio_430_r1_plc/default_dio_430_r1_plc.yaml

vars:

dio_prefix: "DIO#1" # shown in Home Assistant entity names

dio_id: dio_1 # internal unique id

dio_address: 4 # Modbus address set in WebConfig for this DIO

refresh: 1d

For multiple DIOs, duplicate the

dio1:block (dio2:,dio3:…) with uniquedio_id,dio_prefix, anddio_address.

7.2 Entities exposed (from the package)

- Binary Sensors

- DI1…DI4 (post-invert, debounced)

- Switches

- Relay 1–3 (Modbus coils ON/OFF)

- Override ON/OFF for Relay 1–3 (forces state until released)

- Save Config / Soft Reset (commissioning helpers)

- Sensors (diagnostic)

- Button state mask (optional)

- LED state mask (optional)

- Uptime / flags (optional)

- Select/Number (optional, commissioning)

- Modbus address/baud view

- Per-input Enable/Invert/Action/Target (read/write helpers if enabled in the package)

The package sticks to the Modbus map defined in Section 6 (coils for relays, discrete inputs for DI states, holding/input registers for masks and configuration).

7.3 Optional: direct (manual) entity mapping

If you prefer not to use the package, you can expose the core points directly:

modbus_controller:

- id: dio430_4

address: 4

modbus_id: modbus_bus

update_interval: 200ms

command_throttle: 100ms

binary_sensor:

# DI1..DI4 as Discrete Inputs (1x offsets 0..3)

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 DI1"

register_type: discrete_input

address: 0

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 DI2"

register_type: discrete_input

address: 1

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 DI3"

register_type: discrete_input

address: 2

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 DI4"

register_type: discrete_input

address: 3

switch:

# Relays as Coils (0x offsets 0..2)

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 Relay 1"

register_type: coil

address: 0

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 Relay 2"

register_type: coil

address: 1

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 Relay 3"

register_type: coil

address: 2

sensor:

# (Optional) LED and Button masks from Input Registers 30003/30002

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 LED Mask"

register_type: input

address: 3

value_type: U_WORD

accuracy_decimals: 0

- platform: modbus_controller

modbus_controller_id: dio430_4

name: "DIO#1 Button Mask"

register_type: input

address: 2

value_type: U_WORD

accuracy_decimals: 0

7.4 Home Assistant tips (dashboards & automations)

- Dashboards

- Lighting panel: Card for Relay 1–3 plus DI tiles (e.g., wall switch/sensor feedback).

- Maintenance card: Override ON/OFF for each relay + Reset Device + Save Config.

- Automations

- DI → Relay: If you keep the logic in HA/PLC (instead of module mapping), trigger relay switches when a DI goes high.

- Night mode: When

input_boolean.night_modeis on, force a specific Override ON and release it in the morning.

- Naming

- Use

dio_prefixto keep entities readable (DIO#1 Relay 1,DIO#2 DI3, etc.).

- Use

7.5 Troubleshooting

- No response / timeouts: check A/B polarity, shared COM/GND reference, and 120 Ω termination at bus ends.

- Wrong device: make sure

dio_addressin the package matches the WebConfig address. - Relays don’t switch: ensure the relay is Enabled in WebConfig and not “held” by an Override.

- DI not changing: verify wiring to INx/GNDx (respect isolation); check Invert/Enable/Action/Target in WebConfig.

7.7 Notes & Versions

- Works with recent ESPHome releases (e.g., 2025.x).

- Keep

update_intervalmodest (e.g., 200–500 ms) unless you need faster DI polling. - For multiple devices on one bus, stagger

update_interval/command_throttleto reduce collisions.

8. Programming & Customization (DIO-430-R1)

8.1 Supported Languages

- Arduino

- C++ (PlatformIO)

- MicroPython (community builds for RP23xx-class MCUs)

8.2 Flashing (USB‑C, Hardware Buttons Only)

The module exposes a USB device for flashing. All reset/boot actions are done with the front buttons in hardware.

Button layout (front panel):

Combinations

- 2 + 3 → BOOT mode (enter bootloader for flashing)

- 1 + 3 → RESET (hardware reset/restart)

Steps (UF2/IDE)

- Connect USB‑C to a PC (disconnect RS‑485 during flashing).

- Hold Buttons 2 + 3 to enter BOOT. The board appears as a USB drive (UF2) or a serial device for IDE upload.

- Flash:

- UF2: drag‑and‑drop the new

.uf2file onto the mounted drive; the module restarts automatically. - PlatformIO / Arduino IDE: select the correct board/port and upload.

- UF2: drag‑and‑drop the new

- If needed, press Buttons 1 + 3 for a hardware RESET.

No factory‑reset function is provided. Configuration remains intact across normal firmware updates.

8.3 Arduino / PlatformIO Notes

Board / Toolchain